3 d Printing buildings are one of the greatest advancements of technology. The rapidity and accuracy with which the work can be completed is the attraction. We will find out all the details about the important methods of 3 d printing which are concrete printing and contour crafting.

What is 3 D Printing?

The 3D printing process builds a three-dimensional object from a computer-aided design (CAD) model, by successively adding material layer by layer.

Unlike conventional machining, casting and forging processes, where material is removed from a stock item or poured into a mold and shaped by means of dies, presses and hammers.

Time to ask the question. Why is it a big deal?

Why 3 D Printing for construction?

- To avoid construction formwork which accounts for 40% of the total budget for concrete

- It allows for flexibility and freedom of architectural design

- To reduce construction and facilities management costs

- To build a future of sustainable construction

Now, let’s move on to the next section which introduces the 2 printing methods.

3 d printing buildings methods

There are mainly 2 methods for 3 d printing buildings.

- Contour crafting

- Concrete printing

Let’s dive in deep into each of them.

Contour crafting for 3 d printing buildings

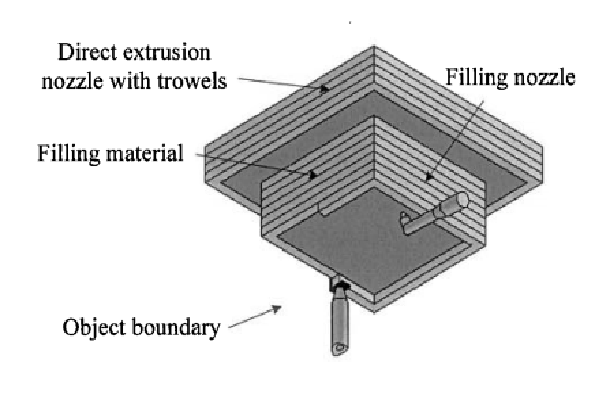

- Contour crafting is based on an extrusion and filling process

- The extrusion process forms the smooth object surface by constraining the extruded flow in the vertical and horizontal directions by the use of trowels.

- The orientation of the side-trowel is dynamically changed for better surface fit for each decomposed layer.

- The side-trowel allows thicker material deposition while maintaining the high surface finish.

- Thicker material deposition cuts down manufacturing time, which is essential for building large-scale parts using the material additive process.

- Maximum deposition layer thickness is limited by the trowel height.

- As the extrusion nozzle moves according to the predefined material deposition path of each layer, the rims (smooth outer and the top surface of outside edges) are first created.

- The towelled outer surface of each layer determines the surface finish quality of the object.

- The smooth top surface of each layer is also important for building a strong bond with the next layer above.

- Once the boundaries of each layer are created, the filling process begins and material is poured or injected to fill the internal volume.

Now, let’s find out the details of concrete printing.

Concrete printing for 3 d printing buildings

- Concrete printing is similar to contour crafting in the ejection phase of concrete

- It is able to achieve better 3D printing, because of its resolution of deposition

- Concrete printing provides larger freedom printing internally and externally.

- The method not only enables the production of both high compressive compressive_strength and_tensile_strength concrete mixture, 110 MPa and 10 MPa respectively but improves the overall workability, extrusion and onsite construction methods.

Next, let me show you the advantages of 3 d printing in construction industry.

Advantages of 3 d printing in the construction sector

- Cost Efficiency

- Labour efficiency

- Time and costs savings

- Environmental/ economic aspects

- Any complex design can be built

Now, let me quickly show you some examples of 3 d printing buildings.

Implementation examples of 3d printing for construction

- Dubai Future Foundation (DFF)

2. Reinforced concrete printed bridge at Gemert

3. Yin gChuang, the Chinese company

Conclusion

- Using this technology is cost, time and quality efficient, through analyzing many theoretical and practical examples of 3D printed structures.

- According to the literature survey that was conducted, using 3D printing can save up to 80% of manufacturing costs and 40% in materials costs.

- For future work and application, the detailed economic analysis must be conducted to show the reduction potential of 3D printing, and its impact on the full-scale economy of the country, by applying any of the methods previously mentioned companies use in their work.

Real experiments must be conducted to prove the material, labor and energy reduction. And, you will amaze at the beauty of 3d printing building.

Don’t forget to share your views on the innovation in comments.

Photo credits: https://www.spentys.com/

Happy learning!

Comments are closed.