Aggregate crushing test is done to find out the strength of aggregate which is the fundamental and essential components of concrete, flexible pavements, etc. More than 70 to 80 per cent of the volume of concrete is aggregate. Aggregates are a very important component of concrete, so the quality really matters when it comes to aggregates. Furthermore, their uses include flexible pavements, railway ballast, etc.

Different tests are to be performed to ensure the quality requirements of aggregates for the specific uses.

Tests on aggregates

Different types of tests are done to determine their properties like

- Strength

- Toughness

- Hardness

- Shape

- Water Absorption etc.

Must Read : Bricks – 8 reliable tests to ensure quality

Must Read : Bitumen – 9 Lab tests on bitumen for flexible pavements

Following are the types of aggregate tests conducted to ascertain the suitability of aggregates.

- Aggregate Crushing test

- Abrasion test

- Impact test

- Water absorption test

- Flakiness index test

- Elongation index test

- Bulk specific gravity test

- Polishing test

Aggregate Crushing test (IS 2386(Part 4):1963 & BS 812–110:1990)

Aggregate crushing test values indicates the strength of aggregate and hence it is very significant. Similarly we can say crushing value is the relative measure of resistance of an aggregate under gradually applied compressive loads. Higher crushing strength means lower crushing value and vice versa. If the aggregate crushing value is less than 10, means an exceptionally strong aggregate, Whereas crushing value of 35 and above means a weak aggregate.

Relevant codes for aggregate crushing test

- IS 2386(Part 4):1963

- BS 812–110:1990

Apparatus required

- Compressive Testing Machine

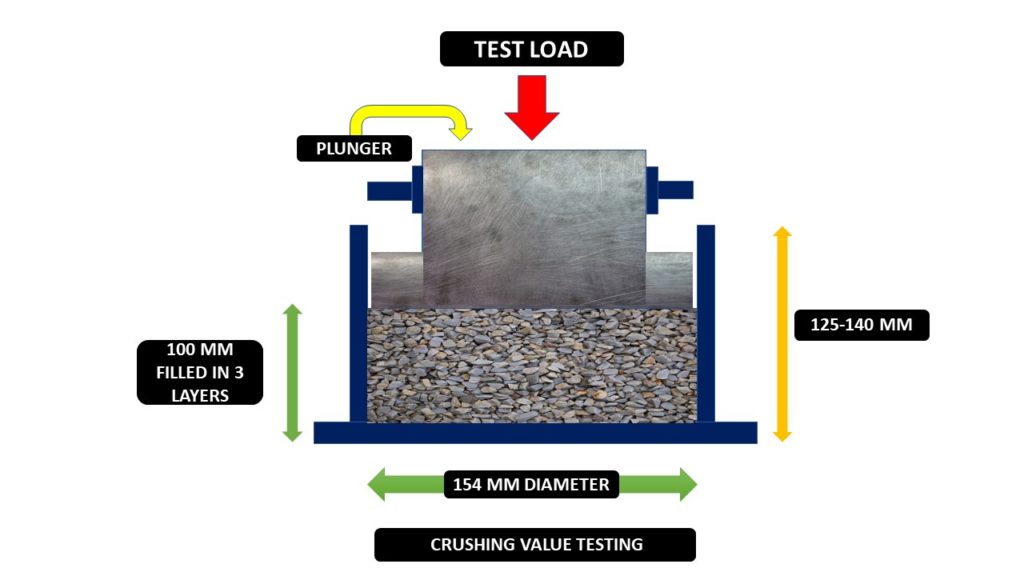

- Crushing Mould: A steel cylinder 15 cm diameter with plunger and base plate.

- Weighing machine,

- Sieve: Size of 12.5 mm, 10 mm and 2.36 mm

Aggregate crushing Test procedure

- Oven dry the aggregates

- Firstly, sieve the aggregate using Indian standard sieves.

- Then collect the specimen passed through 12.5 mm and retained on a 10mm sieve.

- Thus is the test sample of aggregate.

- Then put the cylinder on the base plate and weight it (W).

- The aggregate sample should be filled in 3 layers , each layer is subjected to 25 strokes using tamping rod.

- After that weigh the materials with cylinder and record as (W1)

- Weight of aggregate will be (W1-W). ie : (Weight of cylinder with aggregates – Weight of cylinder)

- Level the aggregate surface carefully before inserting the plunger so that it rests horizontally over the surface.

- Place the cylinder with plunger below a compression testing machine.

- Apply load at a uniform rate so that a total load of 40T is applied in a span of 10 minutes.

- Then release the load and remove the material from the cylinder.

- Following, sieve again on 2.36mm IS sieve.

- Then weigh the material passing through the sieve and record it as W2.

- Finally, calculate the specimen crushing value using the formula below.

Aggregate crushing value = (W2 x 100) / (W1-W)

W1-W = weight of dry sample

W2 = Weight of fraction passing through the sieve after application of load.

For a good quality aggregate, the crushing strength value is low.

Recommended crushing values

| Flexible pavements | Crushing value |

| Soling | 50 |

| Water bound Macadam | 40 |

| Bituminous macadam | 40 |

| premix carpet | 30 |

| Dense mix carpet | 30 |

| Rigid pavements | |

| Other than wearing course | 45 |

| Surface or Wearing course | 30 |

The aggregates used in roads and pavement construction must be strong enough to withstand crushing under roller and traffic. If the aggregate crushing value is 30 or higher’ the result may be anomalous and in such cases the ten percent fines value should be determined instead.

Comments are closed.