ALC panel construction has become a preferred solution in modern projects where efficiency, durability, and sustainability matter. An autoclaved lightweight concrete panel reduces structural load while still delivering strong and reliable performance. Builders increasingly adopt this system because the ALC panel advantages and uses suit a wide range of applications, from residential buildings to large industrial structures. Key ALC wall panel benefits include fire resistance, thermal insulation, sound control, and faster construction cycles. As one of the most practical lightweight concrete panels, ALC panels are easy to handle, transport, and install on site. When supported by a clear ALC panel installation guide, the system ensures accuracy, safety, and consistent quality.

ALC Panel or Autoclaved Lightweight Aerated Concrete panel is composite material consists of cement, lime, and silica sand. These panels use two-way welded steel mesh as reinforcement. Reinforcements are treated with anti-rust liquid. ALC panels are manufactured at high temperatures and are steam cured. ALC panels are used for external and internal non-load bearing walls, roof, floor etc for commercial, industrial, and residential buildings. This article explores ALC panels in a simple and practical way for engineers, contractors, and construction professionals.

ALC Panel Construction Overview

ALC panel construction represents a modern approach to building that focuses on efficiency, durability, and sustainability. These panels are produced from autoclaved lightweight concrete, which significantly reduces the overall load on the structure while maintaining reliable strength. Contractors prefer ALC panels for walls, floors, and partitions because they offer strong fire resistance, effective thermal insulation, and good acoustic performance. Since the panels are manufactured under controlled factory conditions, they deliver consistent quality and precise dimensions. This allows faster installation on site and minimizes construction waste. Compared to conventional masonry, ALC panels improve seismic behavior and simplify handling due to their lightweight nature. As the construction industry moves toward faster and greener solutions, ALC panel systems are becoming a practical choice for residential, commercial, and industrial buildings.

Autoclaved Lightweight Concrete Panel Composition

Autoclaved Lightweight Concrete (ALC) panel composition includes a precise blend of cement, fine silica sand, lime, and water as the main raw materials. Cement acts as the primary binding agent, while silica sand provides strength and stability to the matrix. Lime supports chemical reactions that improve material performance. A small quantity of aluminum powder is added as an aerating agent, creating uniform air voids within the mix. These microscopic pores reduce density without compromising strength. The balanced combination of these ingredients gives ALC panels their lightweight nature, good load-bearing capacity, fire resistance, and thermal and acoustic insulation properties.

Manufacturing Process of ALC Panels

The manufacturing process of ALC panels begins with accurately batching cement, lime, fine silica sand, water, and aluminum powder. The ingredients are mixed to form a uniform slurry, which is poured into molds. The aluminum reacts within the mix and creates millions of evenly distributed air pores, allowing the material to expand. After initial setting, the semi-hardened mass is cut into panels of required sizes with high precision. These panels are then cured under high-pressure steam in autoclaves. This controlled process produces strong, lightweight panels with consistent quality, dimensional accuracy, and long-term durability suitable for modern construction systems.

Key Properties of ALC Panels

Key properties of ALC panels make them a reliable choice for modern construction. Their engineered structure combines low weight with high performance, ensuring safety, efficiency, and durability in buildings.

- Lightweight nature: Reduces dead load on foundations and structural elements

- High fire resistance: Withstands high temperatures without loss of integrity

- Thermal insulation: Limits heat transfer and improves energy efficiency

- Sound insulation: Reduces noise transmission between spaces

- Dimensional stability: Maintains shape with minimal shrinkage or warping

- Workability: Easy to cut, drill, and shape on site

These properties enable faster construction, improved building performance, and long-term serviceability.

Advantages of uses of ALC panel

ALC panels are best suited to cater to the present-day challenges of energy efficiency, fire safety, thermal insulation, etc, than any other building material. Advantages of ALC panels support faster, safer, and more efficient construction while meeting modern performance and sustainability demands.

Let us go through the features and advantages of ALC panels that make them superior and a preferred choice of wall panelling systems.

Light weight construction

ALC panels reduce structural dead load due to their low density of about 600–650 kg/m³, making them nearly four times lighter than concrete and significantly lighter than brick masonry. This improves seismic performance, lowers foundation loads, and delivers overall structural cost savings of around 15–20%.

Thermal insulation

ALC panels feature a unique cellular structure with nearly 75–80% air voids, which gives them very low thermal conductivity. Their thermal k-value is about nine times lower than concrete and nearly twice as efficient as brick masonry. With an industry-leading thermal rating of up to R-30, ALC panels effectively regulate indoor temperatures. They keep interiors cool during summer and warm during winter, reducing heat transfer through walls. This superior thermal insulation lowers heating and cooling demands and can deliver energy savings of around 25%, making ALC panels an energy-efficient building solution.

High fire resistance

ALC panels have a unique cellular structure that delivers excellent fire resistance. A 100 mm thick ALC panel can provide a fire rating of up to four hours. With a melting point above 1600 °C, ALC panels easily withstand typical building fire temperatures of around 650 °C. Since they are made from inorganic materials, ALC panels do not emit smoke or toxic gases during fire incidents. This high fire performance helps protect structural integrity, improves occupant safety, and makes ALC panels a reliable choice for fire-resistant wall and floor systems in modern buildings.

Acoustic insulation- ALC panel

ALC panels offer excellent sound insulation due to their natural cellular structure. They can reduce airborne noise and mechanical vibrations effectively. Depending on panel thickness and surface treatment, ALC panels achieve noise reduction levels of 40–60 dB. Unlike many building materials, they provide both sound absorption and sound resistance at the same time. With an STC rating of around 44, ALC panels meet the requirements of high acoustic performance areas. This makes them ideal for hotels, hospitals, commercial buildings, and residential projects where noise control and indoor comfort are critical.

Water and moisture resistant

Consists of millions of microscopic cells that resist the capillary flow of water and strongly resists water and moisture. ALC panels resist water and moisture due to their closed-cell pore structure, which limits water absorption, prevents seepage, and helps maintain strength, durability, and dimensional stability in damp conditions.

Durability and strength

High pressure steam-curing autoclaving process gives ALC panels high strength to weight ratio even higher than M 150 concrete. ALC panels are used with reinforcements to meet load-bearing design requirements like bearing capacity, stiffness, shear resistance, deflection, etc.

Due to its high load-bearing strength, ALC blocks are a preferred choice for all kinds of walls: external and internal, load bearing and non-load-bearing, basements, and firewalls, etc.

They can absorb strong impacts, while also being able to withstand harsh weather conditions without cracking. They have a designed life span of 50 to 80 years.

Environmental friendly

ALC panels are environment-friendly building products. From the raw material to the production process there is no emission of toxic wastes to the environment. The wastage is minimal and negligible and the entire material is reusable and recyclable. ALC blocks use Energy saving manufacturing process and are LEED-certified and belong to the green building category.

Earthquake resistant

Earthquake forces on a structure is proportional to its weight and ALC panels can considerably reduces the weight of the structure. ALC panels have high shear wall strength and capable of resisting lateral loads. ALC panels can withstand wind loads.

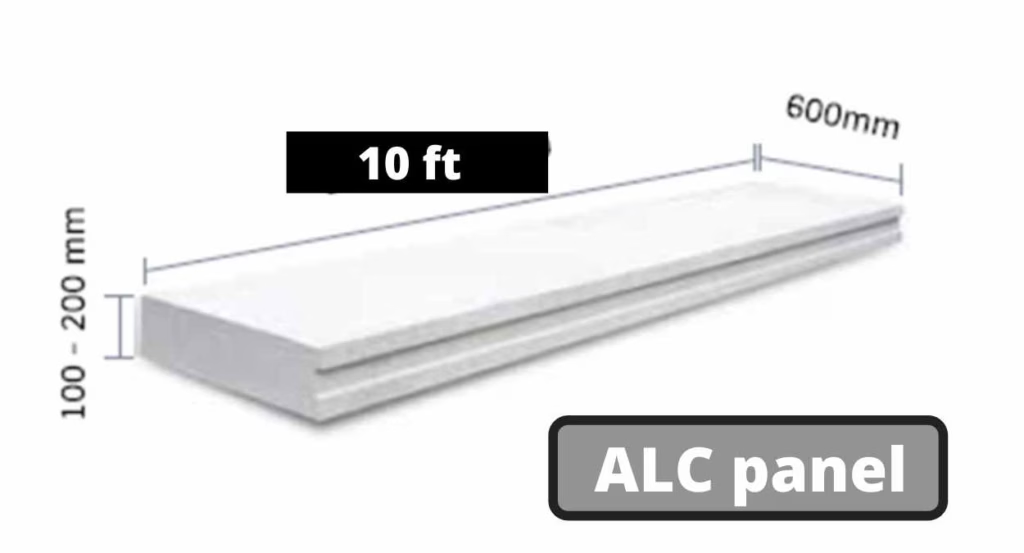

Types and Sizes of ALC Panels

Types and sizes of ALC panels vary to suit different structural and architectural requirements. ALC panels are commonly available as wall panels, floor panels, roof panels, and partition panels. Based on application, they are classified as load-bearing and non-load-bearing panels. Wall and partition panels are widely used for external and internal walls, while reinforced floor and roof panels support imposed loads. Standard panel thickness typically ranges from 75 mm to 200 mm, with widths around 600 mm. Lengths can extend up to 3–6 meters, depending on design and manufacturer specifications, allowing flexibility in modern construction projects.

ALC Panel Installation and construction Guide

The ALC panel installation process follows a systematic and efficient method:

- Setting out and alignment:

Mark panel locations accurately and check levels to ensure proper alignment with the structural frame. - Fixing base supports:

Install starter bars, base channels, or steel angles to support panels and transfer loads safely. - Panel lifting and placement:

Lift ALC panels using cranes or manual handling tools and position them as per layout drawings. - Mechanical fixing:

Secure panels with approved anchors, brackets, or welded connections to the structure. - Joint treatment:

Fill vertical and horizontal joints using specified joint mortar or sealants for stability and airtightness. - Openings and finishes:

Cut service openings easily on site and apply plaster, putty, or cladding finishes as required.

This method ensures faster ALC Panel construction, accuracy, and long-term performance.

Applications of ALC wall Panels in Construction Projects

Applications of ALC panels in construction projects cover a wide range of building types due to their strength, lightweight nature, and performance characteristics. ALC panels are widely used for external and internal walls in residential buildings, high-rise apartments, and villas. In commercial projects, they serve as partition walls, façade elements, and fire-rated enclosures. Industrial facilities use ALC panels for factory walls, warehouses, and utility buildings because of their durability and fire resistance. ALC panels are also suitable for floor and roof systems in low- to mid-rise structures. Their acoustic and thermal properties make them ideal for hospitals, hotels, schools, and offices. Additionally, ALC panels are effective in renovation and retrofitting projects where reducing structural load is critical.

Limitations and Design Considerations of ALC wall Panels

Limitations and design considerations of ALC wall panels construction must be carefully evaluated to achieve optimal performance. Although ALC panels are lightweight, they require proper structural detailing and approved fixing systems to safely transfer loads. Their lower compressive strength compared to conventional reinforced concrete limits their use in heavy load-bearing applications. Moisture protection and proper joint sealing are essential to prevent water ingress, especially in external walls. Designers must also consider panel thickness, reinforcement layout, and support spacing to control deflection and cracking. Careful coordination with services and finishes ensures durability, safety, and long-term performance of ALC panel systems.

Sustainability and Environmental Benefits of ALC wall Panels

Sustainability and environmental benefits of ALC wall panels make them a responsible choice for modern construction. Their lightweight nature reduces raw material consumption and lowers transportation energy. Factory-controlled production minimizes construction waste and ensures efficient use of resources. ALC panels offer excellent thermal insulation, which reduces heating and cooling demands and cuts operational energy consumption throughout a building’s life cycle. Their durability and long service life reduce the need for frequent repairs or replacements. ALC panels are also recyclable and support green building practices by lowering carbon emissions, making them suitable for sustainable and energy-efficient construction projects.

Key Takeaways

- ALC panel construction offers efficiency, durability, and sustainability, making it ideal for various building applications.

- These panels provide key benefits like fire resistance, thermal insulation, and sound control, which enhance overall building performance.

- The manufacturing process involves high-pressure steam curing, resulting in lightweight yet strong panels suitable for modern construction.

- ALC panels are environmentally friendly, featuring minimal waste and recyclability, and they meet green building standards.

- Their advantages include faster installation, cost savings, and improved seismic performance, establishing ALC panel construction as a preferred choice in the industry.

Conclusion

ALC panel construction offers a modern, efficient, and sustainable solution for today’s building needs. An autoclaved lightweight concrete panel combines strength with low weight, improving structural performance while reducing overall construction costs. The wide ALC panel advantages and uses make it suitable for residential, commercial, and industrial projects. Key ALC wall panel benefits include fire resistance, thermal insulation, sound control, and faster construction timelines. As one of the most reliable lightweight concrete panels, ALC systems simplify handling, reduce seismic loads, and enhance energy efficiency. When executed with a proper ALC panel installation guide, these panels deliver consistent quality, durability, and long-term performance. Overall, ALC panels represent a smart construction choice that balances safety, speed, economy, and environmental responsibility in modern building practices.

I need this kind of ALC blocks for my site can you share the list price

Dear Mr. Sachin ALC panels are supplied by a lot of vendors. Aerocon, bilt, etc. Can you share your location . Can give the vendor details

9711115308 (My no)

Hello Vince,

I would like aprice sheet as well.

I have a large residential project in the carribean.

Thank you in advance,

Best Regards

Jerry Logue [email protected]

Mr. jerry i will mail you the details of the panels..

I want to manufacture AAC and ALC blocks/panel in Pakistan. Due to No Trade between two I cannot import any thing. Can you please give me mix ratio of Cement/ Sand/Gypsum/Aluminum Powder and necessary drawings. I will pay for the know how.

yes . i will give u all technical guidance and equipment details

along with equipment details and manufacture details

pleae note my mobile no : you can whats app me

9711115308

Hi Im interested, may i get your whatapp no? with area code.Thank oyu

+91 9711115308

cant find on whatsapp