Cement testing methods play a vital role in ensuring the quality, strength, and durability of concrete used in construction. Engineers rely on systematic cement laboratory tests to evaluate properties such as fineness, setting time, soundness, and compressive strength under controlled conditions. At construction sites, cement field tests help in quick identification of freshness, consistency, and general quality before use. Understanding the types of cement tests allows professionals to select the right procedures for different project requirements. These quality tests on cement ensure compliance with standards and prevent structural failures. In addition, physical tests of cement assess essential characteristics that directly influence performance. Together, these testing methods form the foundation of quality control, helping engineers deliver safe, reliable, and long-lasting structures.

In this article, we are going to discuss cement testing methods, covering both laboratory tests and field tests used to ensure cement quality.

Table of contents

Significance of Quality tests on cement

Cement tests are significant because cement is the most important and highly recognized binding material used in construction. Cement is an integral part of all types of construction ranging from huge skyscrapers, bridges, tunnels, etc to small residential buildings. For industrial structures like power plants, refineries, steel plants, cement plants, bridges, roads, etc. cement is the main component. Cement, when mixed with sand and aggregates, forms concrete and with sand makes mortar. The serviceability, strength, and durability of a structure are related to cement used in various works.

This article is about various tests conducted on cement to check its quality.

Types of quality tests on cement

Cement is one of the oldest and most used binding materials and an integral ingredient used in the construction sector. The quality, serviceability, and stability of a structure are directly related to the quality of cement used in it. Hence it is required to analyse the quality of cement before using it for works. The tests for determining cement quality tests are split into two major types

- Laboratory test

- Field tests for cement

Cement got physical as well as chemical properties. Normally lab tests are conducted to ascertain the properties of cement. Lab tests require time, special equipment, and professionals for testing and interpreting the results. It may not be possible to check all the properties of cement at the site. To overcome this difficulty cement tests are categorised into field tests and laboratory tests.

Field testing methods of cement

The quality of cement is determined using some simple type of field tests. These tests do not require any sophisticated types of equipment and professional skills and get the results very quickly. By conducting these simple tests and analyzing the results we will get an idea about the cement quality and can immediately decide on accepting or rejecting it.

Following are the common field tests conducted to ensure the quality of cement. These are first look tests and quality of cement is ensured by its smoothness to touch, the colour of cement, etc.

- Checking manufacturing date

- Visual checking of lumps

- Feel test

- Heat of cement

- colour

- Water float test

- Setting test

These basic tests give an approximate characteristic of cement. These types of cement test methods are easy and quick but not accurate, however help in concluding the acceptance of cement for works.

Also read : Field tests for cement

Laboratory testing methods for cement

Laboratory testing methods for cement involve tests carried out to accurately determine the physical and chemical properties of cement. Since many properties cannot be verified on-site, these types of cement tests provide reliable data to ensure cement meets standards before use in construction.

The main laboratory tests conducted on cement is as follows.

- Fineness Test

- Compressive Strength Test

- Consistency Test on cement

- Setting time

- Soundness Test

- Tensile strength Test

- Heat of hydration

Lab tests require time. But it provides accurate results.

Comparison Field tests of cement vs Laboratory Tests of cement

| Aspect | Field Tests of Cement | Laboratory Tests of Cement |

|---|---|---|

| Purpose | Quick preliminary quality check | Detailed evaluation of cement properties |

| Accuracy | Low to moderate | High and reliable |

| Equipment | No special equipment required | Requires standard testing apparatus |

| Time required | Very quick results | Time-consuming |

| Skill level | Can be done by site staff | Requires trained technicians |

| Cost | Very low | Higher due to equipment and setup |

| Properties checked | Color, smoothness, lumps, freshness | Strength, setting time, fineness, soundness, chemistry |

| Reliability | Indicative only | Confirmatory and standard-based |

| Advantages (Pros) | Fast, economical, easy to perform on-site | Accurate, standardized, suitable for quality control |

| Limitations (Cons) | Cannot ensure full cement quality | Not feasible at construction sites |

| Application | Acceptance or rejection at site | Compliance with codes and specifications |

Fineness test

The fineness test of cement determines the size of cement grains. Smaller grain size means finer cement. Finer cement grains improve the strength, cohesiveness, and hydration efficiency of concrete. Cement fineness plays a critical role in the hydration process and directly affects concrete strength and durability. Therefore, the cement fineness test is an essential quality control procedure in cement testing.

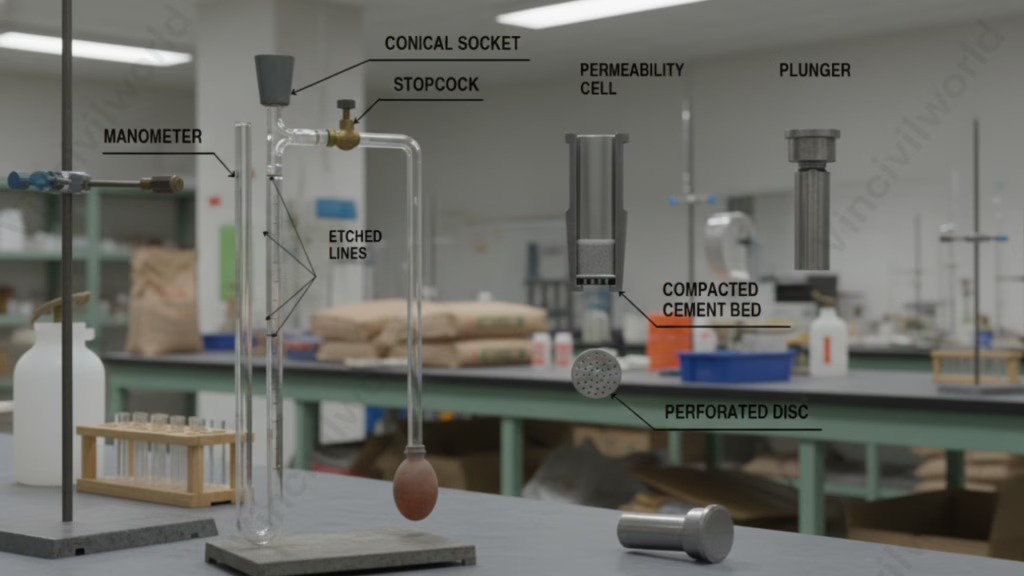

The fineness of cement is determined using the following cement testing methods:

- Sieve test

- Blaine’s air permeability test

- Wagner turbidimeter method

Blaine’s air permeability test is more reliable than sieve analysis and is commonly used in cement laboratory tests under IS, ASTM, and EN standards. The test determines the specific surface area of cement.

Cement with excessive fineness is not preferred, as increased surface area raises water demand and causes quick setting.

Standards for fineness test of cement:

- IS 4031 (Part 1): 1996

- IS 4031 (Part 2): 1999

- ASTM C204-05

- ASTM C115-96a (Reapproved 2003)

- Relevant EN standards

Compressive Strength Test

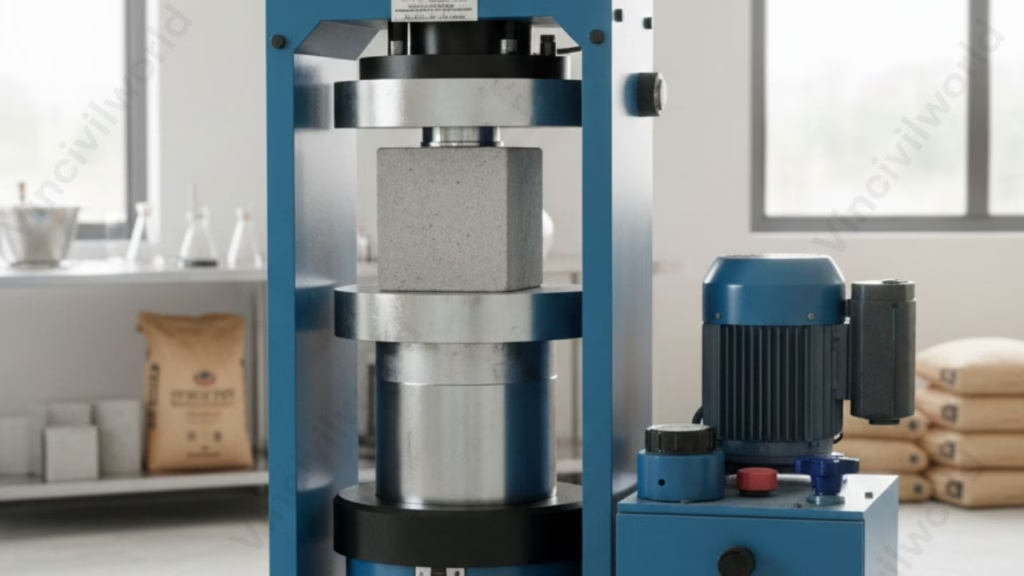

The compressive strength test of cement determines the ability of cement to withstand compressive loads and is a key parameter for selecting cement at construction sites. Concrete derives its strength mainly from cement, making this cement testing method critical for structural safety and durability.

In this test, cement mortar specimens are prepared and cured under controlled conditions. The specimen is then placed in a compression testing machine, where a gradual load is applied until failure occurs. The load at failure divided by the cross-sectional area gives the compressive strength of cement. Factors such as improper mixing, poor curing, and incorrect proportioning significantly affect test results. Cement showing low compressive strength is not suitable for construction.

Standards for compressive strength test of cement:

- IS 4031 (Part 6): 1988

- ASTM C109

- BS EN 196-1: 2005

This test is an essential part of cement laboratory tests and quality control procedures.

Consistency test on cement

The consistency test on cement determines the quantity of water required to achieve standard or normal consistency of cement paste. Water content plays a crucial role in preparing cement mortar, as hydration begins immediately after mixing water with cement. Excess water increases the water–cement ratio and results in reduced strength after hardening. Insufficient water limits the hydration process and also leads to strength loss.

The Vicat apparatus is used to conduct the cement consistency test. Standard consistency occurs when the Vicat plunger penetrates to a point 5 to 7 mm from the bottom of the Vicat mould. The normal consistency of cement generally ranges between 26% and 33%.

Excess water content may cause bleeding and segregation in concrete.

Standards for consistency test on cement:

- IS 4031 (Part 4): 1988

- ASTM C187

- BS EN 196-3: 2005

This test is an important part of cement laboratory testing method and quality control procedures.

Setting time

The setting time test of cement determines the time required for cement paste to lose plasticity and attain initial hardness. Setting time is essential for proper transportation, placing, compaction, and finishing of concrete. Cement setting time is measured in two stages: initial setting time and final setting time.

The initial setting time is the time at which cement starts losing its plasticity and begins to stiffen. The final setting time is the time at which cement completely hardens and gains sufficient strength, allowing safe removal of formwork or scaffolding. The Vicat apparatus is used to determine both initial and final setting times. As per standards, the initial setting time of cement should not be less than 30 minutes, and the final setting time should not exceed 600 minutes.

Standards for setting time test of cement:

- IS 4031 (Part 5): 1988

- ASTM C191

- BS EN 196-3: 2005

This test is a vital part of cement laboratory tests and construction quality control.

Soundness Test

The soundness test of cement determines the ability of cement to retain its volume after hardening. This test also identifies the presence of excess lime in cement. Lime is a major constituent of cement, and its proper proportion is essential for controlled setting and long-term durability. A deficiency of lime affects the setting time, while excess lime makes cement unsound.

Unsound cement undergoes delayed expansion after setting, which can cause cracks, distortion, and disintegration in concrete. This expansion may further lead to corrosion and structural damage. Therefore, cement that fails the soundness test should not be used in construction.

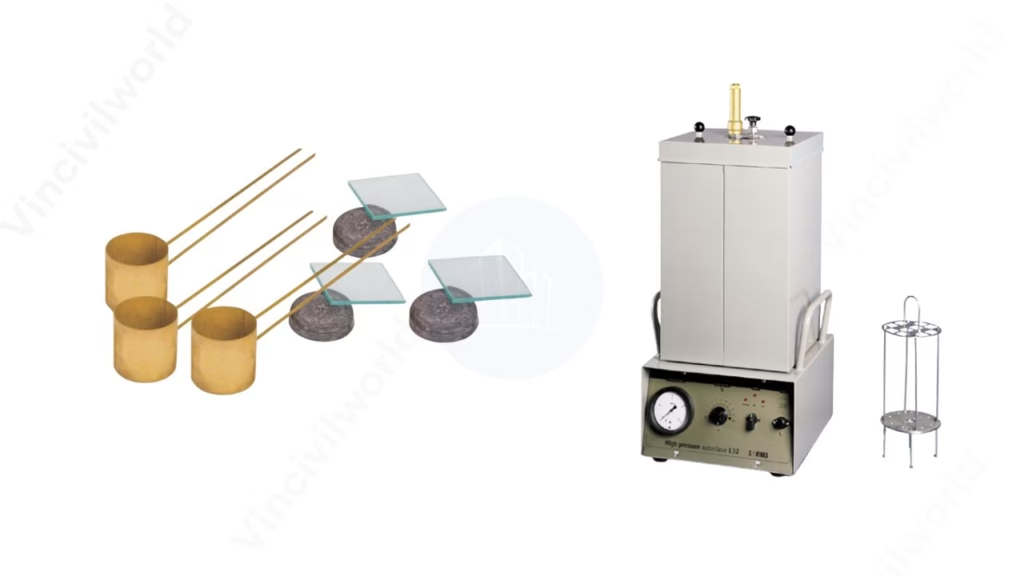

The soundness of cement is determined using the Le Chatelier method and the Autoclave method, both widely adopted in cement laboratory tests.

Standards for soundness test of cement:

- IS 4031 (Part 3): 1988

- ASTM C151-09

- BS EN 196-3: 2005

This test is essential for ensuring volumetric stability and durability of concrete structures.

Tensile strength Testing method of cement

The tensile strength test of cement determines the resistance of cement to tensile stresses. This test is carried out using the briquette test method or the split tensile strength test. Compared to compressive strength, the tensile strength of cement is relatively low. However, tensile stresses develop in concrete due to dynamic loading, shrinkage, and temperature variations, which may lead to cracking.

In this test, uniaxial tensile load is applied to the cement specimen until failure occurs. The maximum load at failure divided by the cross-sectional area gives the tensile strength of cement. Although this test is not commonly used for quality control today, it helps in understanding cracking behavior and material performance.

Standards for tensile strength test of cement:

- ASTM C307

- EN 196-1

This test forms part of cement laboratory tests used for research and performance evaluation.

Heat of Hydration

The heat of hydration test of cement determines the amount of heat released when cement reacts with water. Hydration is an exothermic chemical reaction, and the heat generated contributes to the strength development of cement. The heat of hydration is expressed in kilojoules per kilogram of cement.

A calorimeter is used to measure the heat of hydration of cement under controlled conditions. Several factors influence the heat of hydration, including the proportion of C₃S and C₃A compounds, water–cement ratio, curing temperature, and fineness of cement. Excessive heat of hydration can induce thermal stresses, leading to cracking in mass concrete structures. Therefore, controlling heat generation is crucial for durability and structural safety.

Standards for heat of hydration test of cement:

- ASTM C186

- IS 4031 (Part 9): 1988

This test is an important part of cement laboratory tests, especially for mass concrete applications.

Key Takeaways

- Cement testing methods ensure the quality, strength, and durability of concrete essential for construction.

- Engineers use systematic cement laboratory tests and quick cement field tests to assess properties like fineness and compressive strength.

- Laboratory tests provide accurate results, while field tests offer fast, preliminary quality checks without complex equipment.

- Key tests for cement include fineness, compressive strength, consistency, setting time, soundness, tensile strength, and heat of hydration.

- Ultimately, cement quality directly impacts the stability and life of structures, making testing imperative before construction begins.

Conclusion

Cement testing methods play a crucial role in ensuring the quality, strength, and durability of concrete structures. Both field tests of cement and cement laboratory tests help engineers evaluate essential properties such as fineness, consistency, setting time, soundness, compressive strength, tensile strength, and heat of hydration. While field tests offer quick, preliminary checks for on-site decision-making, laboratory tests provide accurate and standardized results as per IS, ASTM, and EN codes. Together, these quality tests on cement prevent the use of inferior materials, reduce construction risks, and enhance structural performance. Proper understanding and application of the types of cement tests are vital for achieving safe, durable, and long-lasting construction. Therefore, systematic cement testing remains a fundamental part of quality control in modern civil engineering practice.

3 thoughts on “Cement Testing Methods -Field and Laboratory tests”

Comments are closed.