The concrete compressive strength formula is fundamental. It calculates how well concrete can resist axial loads without failing. Concrete compressive strength formula is crucial for determining the strength of concrete structures. It also ensures the durability of buildings, bridges, and roads. The formula for concrete compressive strength is expressed as fc = P/A. Here, P is the applied load. A is the cross-sectional area of the concrete specimen. To ensure accuracy, concrete compressive strength testing methods follow strict guidelines.

These guidelines are provided by codes such as ASTM C39 and IS 456. Concrete compressive strength test procedures focus on assessing strength using concrete cubes or cylindrical specimens. These procedures include detailed acceptance criteria to verify whether the concrete meets the required standards. Additionally, a concrete compressive strength data set can help in evaluating the strength over different curing periods. The standard deviation for concrete compressive strength helps assess consistency and quality.

This article is about the concrete compressive strength formula, concrete compressive strength test IS code etc. This also covers concrete compressive strength acceptance criteria,concrete compressive strength testing methods, standard deviation for concrete compressive strength etc.

Table of contents

- Introduction to Concrete Compressive Strength Formula

- Code Requirements – Concrete compressive strength

- Concrete Compressive Strength Test Methods

- Concrete Compressive Strength Data Set

- Compressive Strength of Concrete Cube Formula

- Standard Deviation for Concrete Compressive Strength

- Acceptance Criteria

- Compressive Strength of Concrete: Factors Affecting the Formula

- Conclusion

- Key Takeaways

Introduction to Concrete Compressive Strength Formula

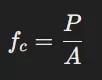

The concrete compressive strength formula allows engineers to calculate the ability of concrete to withstand compressive forces. Engineers measure Concrete compressive strength in megapascals (MPa) or Newtons per square millimeter (N/mm²). To determine this strength, engineers apply a compressive force to concrete specimens, such as cubes or cylinders, until the concrete fails. The formula for calculating the compressive strength is

fc = P/A

Where:

- fc = Compressive strength (in MPa or N/mm²)

- P = Maximum applied load (in Newtons)

- A = Cross-sectional area of the specimen (in mm² or cm²)

Engineers worldwide use the concrete compressive strength formula to confirm that concrete can withstand the necessary loads in construction projects.

Code Requirements – Concrete compressive strength

In the construction industry, the concrete compressive strength formula is governed by specific building codes. These codes outline the requirements for testing of concrete, the selection of appropriate materials, and the acceptance criteria for compressive strength. ASTM C39 is the Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. IS 456:2000 is the Indian Standard for Code of Practice for Plain and Reinforced Concrete. These standards define the procedures. They also set the acceptable limits for concrete compressive strength.

Adhering to these codes ensures that concrete meets the structural requirements, offering durability and safety in construction. Codes provide specific guidelines on concrete compressive strength testing methods, detailing the use of cubes or cylinders and specifying curing times before testing.

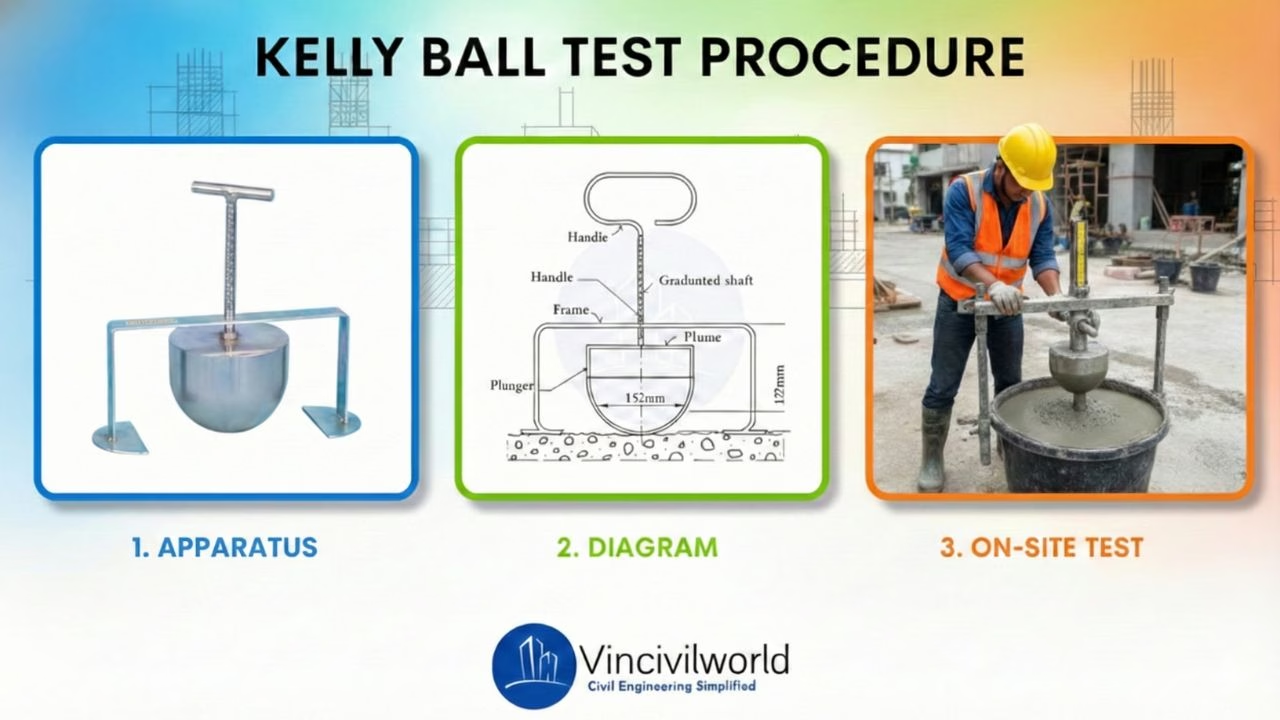

Concrete Compressive Strength Test Methods

Testing for concrete compressive strength is a crucial step in the quality control process. Several methods exist, but the most common involves casting concrete specimens (usually cubes or cylinders) and subjecting them to a compressive load. The concrete compressive strength test is typically conducted according to specific standards and includes the following steps:

- Sample Preparation: Technicians pour concrete into molds and allow it to cure for a specified period, often 7, 14, or 28 days.

- Testing: They place the cured specimen in a testing machine that gradually applies force until the specimen fails. They then record the maximum load.

- Calculation: Using the concrete compressive strength formula, they apply the maximum load and cross-sectional area to determine the concrete’s strength.

For cylindrical specimens, the compressive strength of cylindrical concrete specimens formula

Where A is the cross-sectional area of the cylinder (in mm² or cm²). The load is applied along the axis of the cylinder.

Concrete Compressive Strength Data Set

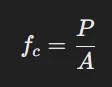

Compressive Strength of Concrete Cube Formula

The compressive strength of concrete cube formula is similar to that of cylinders. In this case, a concrete cube of standard size (typically 150 mm x 150 mm x 150 mm) is tested. The formula remains

Where P is the applied load, and A is the cross-sectional area of the cube. Cube specimens are used primarily because they are easier to handle and store than cylinders. Their failure pattern is often easier to interpret.

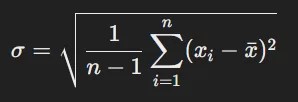

Standard Deviation for Concrete Compressive Strength

When working with concrete, it is important to measure the compressive strength. It is also crucial to evaluate the variability in strength across different batches. Standard deviation is used to assess this variability. A higher standard deviation indicates that the concrete is more inconsistent, which could lead to structural weaknesses. Engineers aim for a low standard deviation to ensure that concrete consistently meets the required strength standards.

The formula for calculating standard deviation for concrete compressive strength is:

Where σ is the standard deviation.

n is the number of test samples, xi is the individual strength value, and x is the mean strength.

Acceptance Criteria

The concrete compressive strength acceptance criteria help in determining if a concrete batch meets the necessary strength. This ensures it is suitable for a given application. These criteria are defined by codes such as ASTM C39 or IS 456 and typically include:

- Minimum required compressive strength at 28 days (typically expressed in MPa).

- The number of tests needed to assess the batch.

- The allowable variation in strength between samples (standard deviation).

If concrete does not meet the acceptance criteria, engineers may reject it or conduct further testing to determine its suitability for use.

Compressive Strength of Concrete: Factors Affecting the Formula

Several factors can influence the concrete compressive strength formula:

- Water-Cement Ratio: Lower water-to-cement ratios generally result in stronger concrete.

- Aggregate Size and Type: The choice of aggregates affects the strength of the mix.

- Curing Conditions: Proper curing ensures that hydration continues and the concrete reaches its maximum potential strength.

- Mix Proportions: The specific proportions of cement, water, and aggregates used in the mix design will affect the compressive strength.

Conclusion

The concrete compressive strength formula is a fundamental tool for engineers. It ensures the structural integrity of concrete in construction projects. Engineers follow industry standards and testing methods. They also consider factors such as water-cement ratio and aggregate type. This way, engineers can produce reliable and strong concrete that meets the required safety criteria. Understanding different testing methods is essential. Knowing the concrete compressive strength acceptance criteria is also vital for quality control in the construction industry.

By applying the principles outlined in codes, engineers use comprehensive concrete compressive strength data sets. They can guarantee that concrete will perform as expected under various load conditions. This provides safety and durability in all structures.

Key Takeaways

- Testing Methods: Engineers measure concrete strength by testing concrete cubes or cylindrical specimens at various curing periods, typically at 7, 14, or 28 days.

- Factors Affecting Strength: Factors such as water-cement ratio, aggregate size, mix design, and curing conditions influence concrete compressive strength.

- Acceptance Criteria: The concrete must meet specific strength requirements set by relevant codes. Engineers may reject non-conforming concrete or subject it to additional testing to verify its suitability.

- Standard Deviation: Standard deviation is used to assess the variability in compressive strength. A lower deviation indicates more consistent concrete strength, which is vital for ensuring safety.

By understanding the concrete compressive strength formula and associated factors, engineers can ensure concrete’s reliability, safety, and performance in various structural applications.