Field tests for cement are crucial for ensuring quality. These tests provide an immediate assessment of cement properties. They help identify issues affecting project integrity. Testing of cement involves various procedures. Each test evaluates performance characteristics. On-site cement tests include visual inspections and hand feel tests. These methods verify material suitability for construction. Conducting a field test of cement allows quick, informed decisions. Thus, engineers maintain high standards and avoid failures. This blog delves into different field tests for cement. It offers insights into their importance and methodology.

Table of contents

Importance of Cement Quality

Ensuring cement quality is crucial for construction durability and safety. High-quality cement prevents structural failures and extends building life. It enhances durability by providing long-lasting structures and reduces the risk of failures. Additionally, it ensures the necessary strength for buildings, offering consistent performance in construction. Moreover, high-quality cement minimizes repair costs, enhancing project cost-efficiency. Furthermore, it contributes to sustainability by reducing waste and environmental impact. Additionally, good cement improves the visual appeal of buildings, ensuring aesthetic value. Therefore, understanding and maintaining cement quality is essential for successful construction projects.

Significance of Field Tests for Cement

Field tests for cement are crucial for ensuring construction quality and reliability. These tests evaluate cement properties directly at the site, providing immediate feedback on its suitability for use. They detect deviations early, preventing issues like poor durability or structural weaknesses. Engineers and construction professionals rely on these tests to verify the cement’s strength, consistency, and adherence to specifications, ensuring only high-quality cement is used. This proactive approach enhances construction efficiency and minimizes risks, ensuring safer and more durable structures over the long term. Unlike lab tests, which take time for results, field tests provide instant feedback, allowing for timely adjustments and ensuring the cement meets required standards before use in construction projects.

How to check cement quality?

Cement quality is assessed through two main types of testing

a) Laboratory testing

b) Field tests for cement

Laboratory tests involve specialized equipment and expertise, requiring time to evaluate and interpret data comprehensively. However, not all qualities of cement can be adequately assessed in the field. This article focuses on field tests of cement, which provide immediate on-site evaluations to ensure construction quality and reliability.

Field tests of Cement

Simple field tests can confirm cement quality without expensive equipment or specialized skills. Results are quick, helping decide whether to accept or reject the cement. These tests provide initial evaluations based on touch smoothness and color. Further confirming cement quality involves assessing these factors.

- Checking the manufacturing date of cement

- Visual checking for lumps

- Feel test of cement

- The heat of cement test

- Colour test of cement

- Water float tests

- Setting tests

Checking the manufacturing date of cement

Checking the manufacturing date of cement is crucial for ensuring its quality and usability. Cement’s properties deteriorate over time, affecting its performance in construction. Fresh cement, usually less than three months old, provides optimal strength and binding properties. To check, locate the manufacturing date printed on the cement bag. Ensure the cement is within the recommended usage period. When stored under perfect conditions, the cement must be utilized within 90 days of manufacture. Using old cement can lead to weak structures and potential failures. Therefore, always verify the date before use to maintain construction integrity and safety. This simple step helps avoid costly repairs and ensures the durability of the construction project.

Visual checking for Lumps – Field test for cement

Visually checking for lumps ensures cement quality. Initially inspect the cement for any lumps. To establish the potential existence of lumps, press the cement bag’s corners. Lumps indicate moisture absorption. Next, break the lumps to see if they crumble easily. If they don’t, the cement may be old or compromised. Moreover, fresh cement should feel smooth and powdery. Always reject cement with hard lumps. Thus, visual checking helps maintain construction quality by ensuring only good cement is used.

Feel test – Field test for cement

The feel test for cement is a simple and quick method to assess its quality. To perform this test, take a small amount of cement between your fingers. Rub it gently to check its texture. High-quality cement should feel smooth and powdery. If the cement feels gritty or coarse, it indicates the presence of impurities or improper grinding. Additionally, fresh cement should flow freely. There should be no earthy smell, which can indicate contamination. Subsequently, this feel test helps quickly determine if the cement is suitable for use, ensuring better performance and durability in construction projects. By regularly performing this test, you can maintain high standards and avoid potential issues in your construction work.

Heat of cement

If you put your hand inside a bag of cement that is open and of good quality, but has not yet started to hydrate, your hand will feel cool. This is because cement hydrates exothermically, meaning it releases heat as it reacts with water. Before hydration begins, the cement remains at a lower temperature, giving it a cool feel to the touch. This tactile test is often used as a quick indicator of cement quality and freshness on construction sites.

Colour

The color of cement is typically greenish gray , reflecting its composition of primarily calcium silicates and other minerals. Generally, factors like raw materials and manufacturing processes can slightly influence color variations. Any deviations may indicate variations in composition or quality that could affect the concrete’s performance and appearance. However, the type and source of the ingredients can affect the colour of the cement.

Water float test

The water float test for cement is a simple field test used to assess its quality. In this test, a small amount of cement is sprinkled on the surface of water in a container. High-quality cement particles will float momentarily before sinking slowly and uniformly. However,if the cement floats on the surface without sinking or if it sinks immediately, it may indicate impurities or inadequate grinding, affecting its quality and suitability for construction. This test helps quickly evaluate cement’s fineness and uniformity before use in concrete applications.

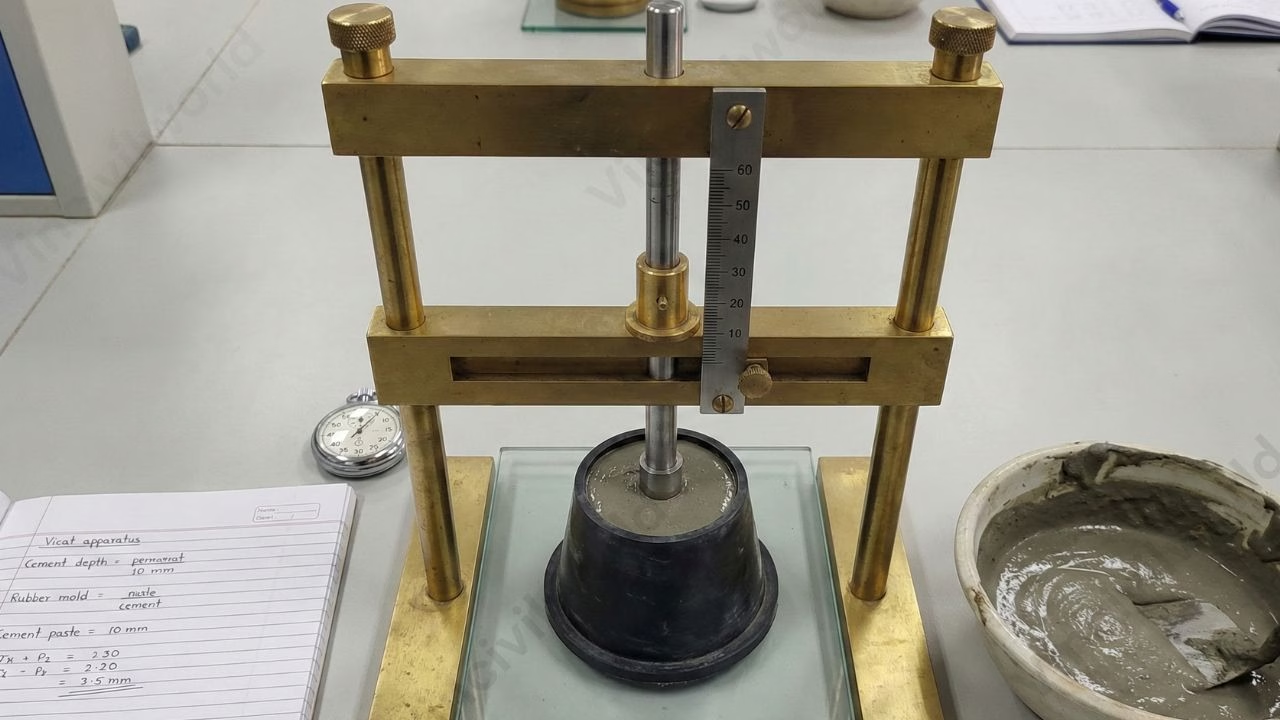

Setting test

A thick paste of cement applied to a glass piece that maintains its shape and does not break or alter during a 24-hour immersion in water is considered excellent. This field test for cement test assesses the cement’s ability to maintain structural integrity and resist disintegration when exposed to water, highlighting its quality and suitability for construction applications.

Key Takeaways

Field tests for cement are essential for ensuring construction quality and reliability. Generally, these tests provide immediate evaluations of cement properties onsite, helping to detect issues early and ensure adherence to standards. From visual inspections to tactile assessments like the feel test, each method plays a crucial role in verifying cement quality before use in construction projects.

Conclusion

Field tests for cement are vital tools that engineers and construction professionals rely on to maintain high standards and avoid potential failures. By conducting these tests, construction teams can make informed decisions, ensuring that only high-quality cement is used. This proactive approach not only enhances construction efficiency but also contributes to the durability and safety of structures over their lifespan. Similarly, understanding and implementing these field tests are essential for achieving successful and sustainable construction outcomes.

10 thoughts on “Field tests for cement – Evaluating quality onsite”

Comments are closed.