Kelly ball test is a simple test also known as a ball penetration test. This test determines the workability of fresh concrete. It is an alternative to the slump cone test and is an effortless field test of concrete.

Concrete is designed for a particular strength. The total structural stability is dependent on good quality concrete. Therefore quality control is one of the most important aspects to be taken into account during the production of concrete. Marginal variations in water to cement ratio, ingredient proportioning, increase in a slump, etc impacts the desired concrete strength which in turn affects the strength and stability of structures.

Quality tests on concrete

Quality tests performed on concrete are

- Production stage quality tests ( On fresh concrete before placing)

- Hardened stage quality tests ( hardened concrete specimens)

- On structures ( tests done on the structures )

Also read : Bitumen tests – 9 lab tests for bitumen

Production stage quality tests on fresh concrete

- SLUMP TEST

- Compaction Factor test

- Vee- Bee Test

- k slump test

- Kelly ball test

- Flow table test

This article covers the kelly ball test ,apparatus details, procedure, merits and demerits etc.

Standard Guidelines

ASTM C360 – 92

Kelly ball test Apparatus

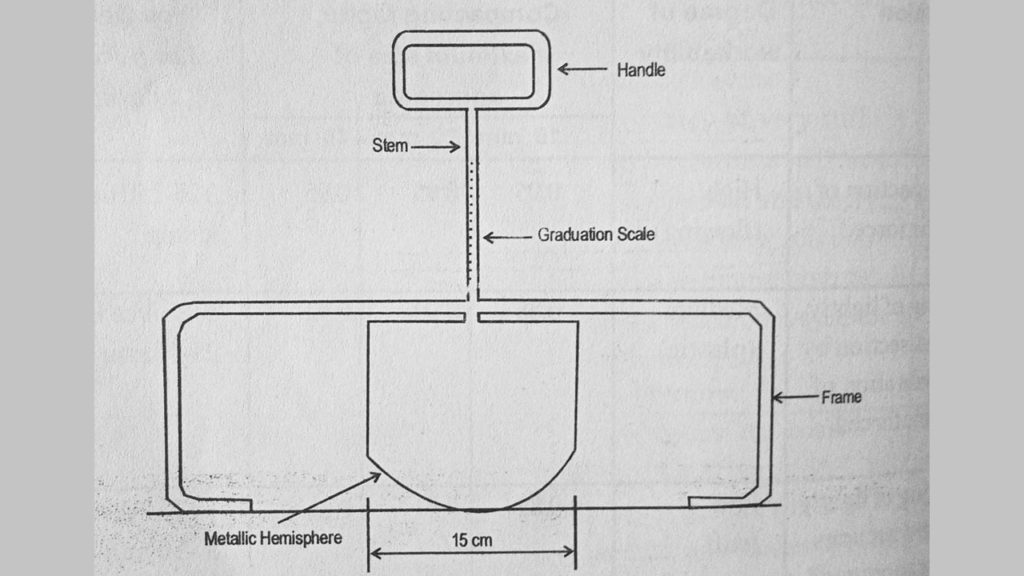

The kelly ball apparatus for measuring the workability of concrete consist of..

- Meta hemisphere (Ball)

- Graduated scale

- Frame

- Handle

The workability of concrete is decided by the depth of the penetration of metal hemisphere (ball) which will descend under its own weight into the fresh concrete. The Metal hemisphere or ball has 152 mm diameter and 13.6 kg weight. J. W. Kelly (Professor, University of California) had devised the plan of the Kelly ball test apparatus. Hence, later on it also came to be known as a ball penetration test. On the top of the apparatus, there is a handle. The graduated scale measures the penetration reading.

Test Procedure

- Firstly, Pour the fresh concrete into the wide container.

- The concrete depth should be a minimum of 20 cm.

- Then level and place the apparatus on the surface of the concrete in the container.

- Now slowly release the handle of the apparatus and allow it to penetrate the concrete.

- Then observe and note down the penetration value on the graduated scale.

- Repeat the procedure at least three times and record the values.

- Finally, calculate the average values of the penetration to determine the workability of concrete.

Results

The workability of the concrete is the average value of the readings from the penetration.

Advantages – Kelly ball test

Some advantages of this test are

- Compared to other workability tests kelly ball test is very fast

- Precise and Accurate results

Disadvantages of Kelly Ball Test

The disadvantages of this test include

- This test requires a large amount of fresh concrete.

- The result should not be precise if the size of the aggregate is large.

- The concrete should be levelled before starting the test.

Comments are closed.