Lightweight aggregate plays a vital role in modern construction by reducing structural dead load while maintaining strength and durability. Widely used in lightweight aggregate concrete, it improves thermal insulation, seismic performance, and material efficiency. Understanding the types of lightweight aggregate—both natural and artificial lightweight aggregate—helps engineers select suitable materials for specific applications. Equally important is the lightweight aggregate manufacturing process, which influences density, strength, and absorption characteristics. The properties of lightweight aggregate, such as low unit weight, porosity, and adequate compressive strength, make it ideal for structural, geotechnical, and precast works. This article explains how manufacturers produce lightweight aggregates, highlights their key properties, and describes the different types available, providing a clear technical foundation for effective design and construction decisions.

Lightweight aggregate is a widely used construction material owing to its versatile properties. In this blog, I will walk you through what is a lightweight aggregate, its properties, applications and manufacturing process.

Table of contents

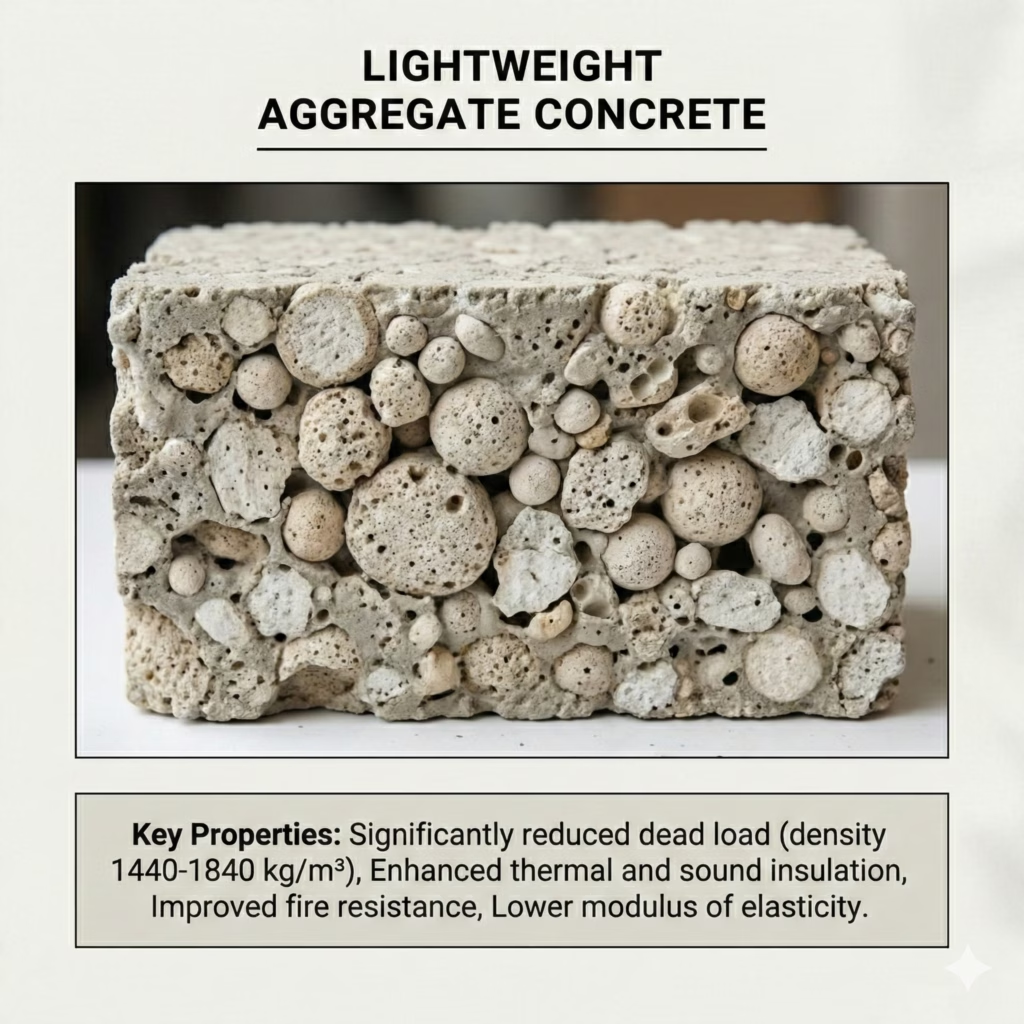

What is a lightweight aggregate concrete ?

Lightweight aggregate is a coarse aggregate used to make lightweight concrete for structural as well as non-structural applications.

- The Compressive design strength of normal concrete for cast-in-situ, precast and prestressed concrete ranges between 20 N/mm2 to 35 N/mm2. On the other hand, the minimum compressive design strength of lightweight aggregate concrete will be around 17-18 N/mm2.

- Normal concrete has a density between 2300 and 2500 kg/m3. However, when it comes to LWC the density ranges between 500 kg/m3 to 1800 kg/m3 depending on the type of aggregate used.

- Lightweight aggregate concrete with densities lower than 17 N/mm2 falls under the category of LWC. And, those with densities above 17 N/mm2 are referred to as structural lightweight concrete (SLWC).

- Engineers can also design LWC to achieve minimum compressive strength comparable to normal concrete by adjusting the proportions of mineral admixtures.

- They use SLWC for structural applications and combine it with reinforcement steel in the same way as conventional concrete.

Features of Lightweight Aggregates

- The lightweight aggregate used in concrete may have any form, including cubical, rounded, angular, and other shapes. Its form and texture directly influence its workability.

- These aggregates absorb minimal water and retain their low density.

- A high saturation level makes it an attractive option.

- LWA can reduce the dead loads on the structure and make it more economical.

- Has relatively low thermal conductivity and is preferred for roof insulations.

- Helps in consuming industrial wastes like blast furnace slag, fly ash, clinkers etc.

- Possess good acoustic properties.

In the next section we will see what are the desired characteristics of a lightweight aggregate.

Also read : Pervious Concrete- All Factors Affecting, Limitations & Methodology Explained

Lightweight Aggregate Desired Characteristics

- The properties and composition should be consistent.

- To ensure worthwhile structural savings, the aggregate should have a low specific weight, in compliance with the required ASTM requirements.

- The aggregate should have a low number of large external voids. And a high number of smaller well-distributed voids within the particles.

- Individual aggregate particles should be able to withstand handling and mixing.

- The particles should have a good bond with the cement and should not react chemically with it.

- The aggregate should be rated appropriately for the intended use, according to the relevant ASTM specification

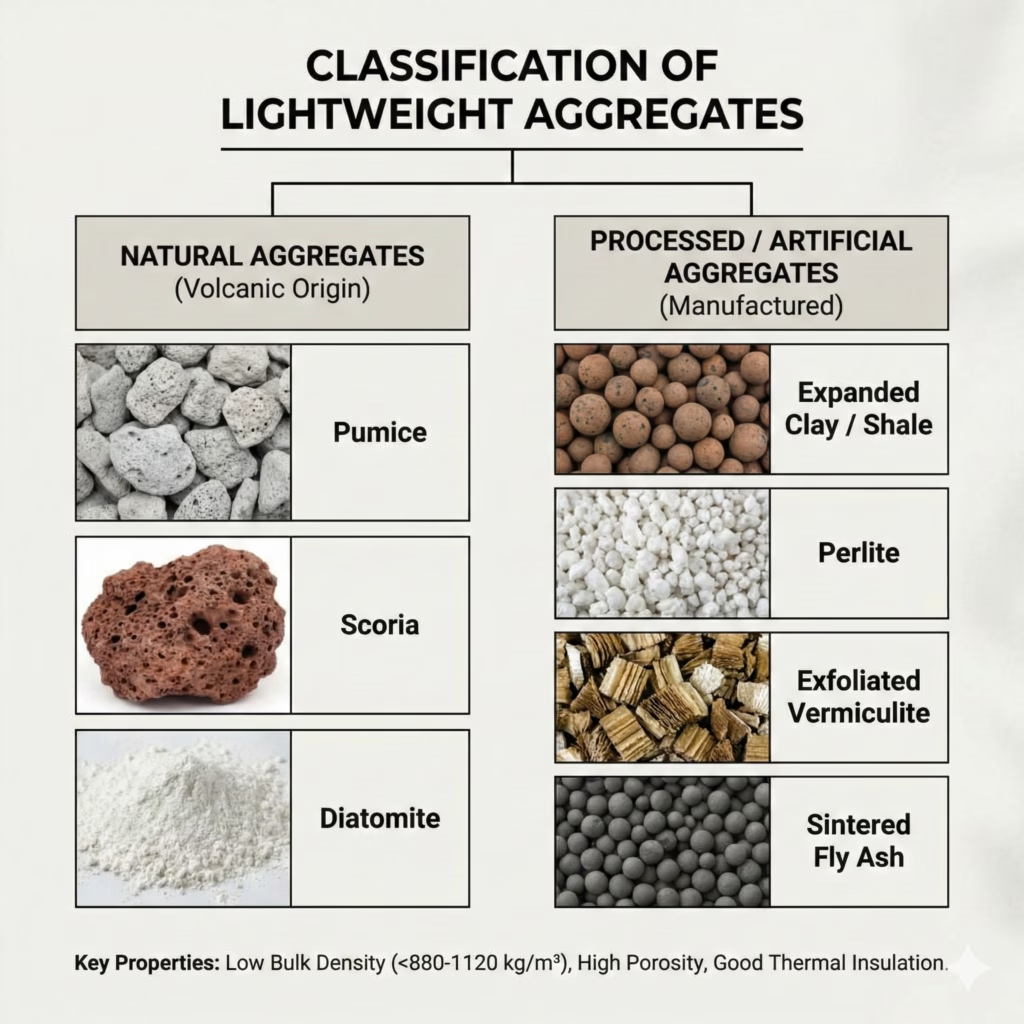

Types of Lightweight Aggregates

Engineers classify LWA into three types based on their sources:

Artificial lightweight aggregate – Manufacturers produce these from local materials such as clay ceramisite and expanded perlite.

Industrial waste lightweight aggregate – Manufacturers process industrial wastes such as fly ash, ceramisite, expanded slag balls, cinder, and light sand.

Natural aggregate – Producers obtain these from naturally porous stones such as pumice, volcanic cinder, and light sand.

Also read : ALC Panel – Autoclaved lightweight Concrete Panel

Lightweight Aggregates Manufacturing Process

Manufacturers produce most lightweight aggregates from clay, shale, or slate. However, they also use furnace slag, natural pumice, vermiculite, and perlite as substitutes.

They expand the raw material (excluding pumice) to about twice its original volume to produce LWA. The expanded material has properties that are similar to natural aggregate. As a result, it produces a lighter concrete product.

Let me show you the detailed procedure.

Extraction or quarrying

Operators use cone crushers, jaw crushers, hammer mills, and pug mills to crush the material and then screen it to ensure the required quality.

Sizing

Operators return the material that does not meet size requirements to the crushers, while they recycle the material that meets the screening criteria.

It is then moved to hoppers.

Reaction

- The material is fed from the hoppers into a rotary kiln.

- Manufacturers heat the material to about 1200 °C (2200 °F) using coal, coke, natural gas, or fuel oil.

- As heating occurs, carbonaceous compounds within the material liquefy and generate gas bubbles, which expand the material.

- During this process, the material also releases VOCs (volatile organic compounds).

- The enlarged product emerges from the kiln.

Cooling

- The process conveys the clinker into a clinker cooler, where air cools it and forms a porous structure.

- After cooling, operators screen the lightweight aggregate for size, crush it if necessary, and stockpile it.

- Most plants (about 90%) use rotary kilns, although some facilities also use travelling grates to heat the raw material.

Lightweight Aggregate Applications

- Lightweight aggregates are used to produce screeds and for thickening applications. Engineers apply them when floors or roofs require leveling or smoothing, as they allow easy and efficient placement.

- They are also applied in screeds and walls where workers need to fix timber elements.

- Casting structural steel in lightweight aggregate concrete protects it from fire and corrosion and also satisfies architectural requirements.

- Engineers use this on roofs as an effective heat insulation material.

- Used as insulation for water pipes.

- Used to construct partition walls and panel walls in frame structures.

Hope you found this article insightful. Let us know in the comments.

Key takeaways

- Lightweight aggregates reduce structural dead load without compromising essential strength.

- Manufacturing methods strongly influence density, strength, and absorption properties.

- Natural, industrial by-product, and artificial types offer flexibility in material selection.

- These aggregates improve workability and enable efficient construction practices.

- They support structural, insulation, fire protection, and architectural applications.

- Proper processing ensures consistent quality and performance.

- LWA contribute to durable, economical, and sustainable construction solutions.

Conclusion

In conclusion, lightweight aggregates offer an efficient solution for modern construction by balancing strength, weight reduction, and performance. Their role in lightweight aggregate concrete has become increasingly important for structural and non-structural applications alike. Understanding the types of lightweight aggregate, including natural and artificial allows engineers to select materials suited to specific design needs. The lightweight aggregate manufacturing process directly affects quality, durability, and consistency, making process control essential. In addition, the properties of lightweight aggregate, such as low density, thermal insulation, and adequate strength, contribute to improved structural efficiency and sustainability. When selected and applied correctly, these materials support safe design, cost-effective construction, and long-term performance across a wide range of engineering projects.

2 thoughts on “Lightweight Aggregate : Manufacturing, Properties and Types”

Comments are closed.