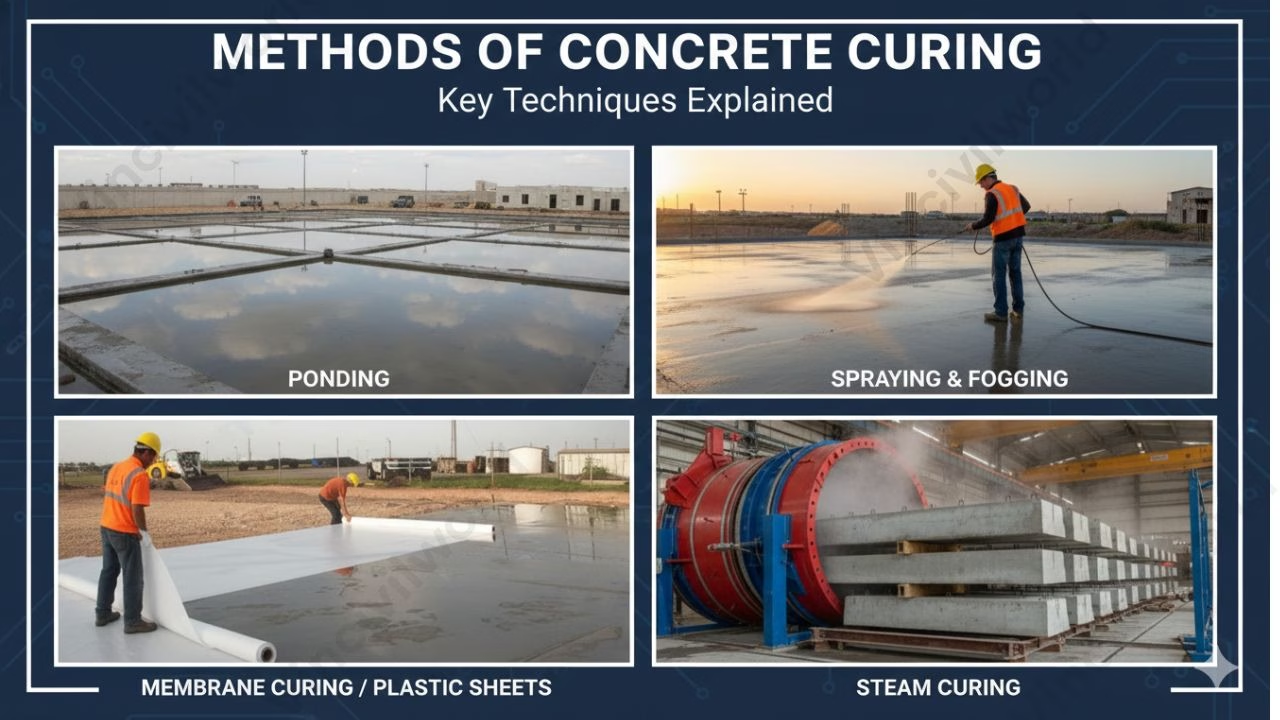

Methods of Concrete curing plays a critical role in ensuring that fresh concrete gains its required strength and durability. After placement, concrete needs controlled moisture and temperature conditions to support the hydration reaction. Engineers follow different Methods of Concrete Curing depending on the site environment, structure type, and expected performance. Among the many Types of Concrete Curing, water curing remains the most common approach, especially for slabs, pavements, beams, and columns. Practical Concrete Water Curing Techniques like ponding, spraying, and fogging help maintain continuous moisture in hot and dry regions. When water is limited, engineers prefer Membrane Curing of Concrete to reduce evaporation. In cold weather concreting and precast sites, they use Steam Curing Concrete to accelerate early strength. These On-Site Concrete Curing Methods ensure durable, crack-free structures that perform well throughout their service life.

This article explains water curing, membrane curing, and steam curing techniques used at construction sites, along with their applications and benefits.

Table of contents

Types of Concrete curing

Curing is the process that helps in maintaining moisture to allow fresh concrete to attain its desired strength in a planned manner through a hydration reaction. If the water evaporates quickly, the requisite amount of water will not be available for the hydration process. The curing of concrete helps to retain the concrete moisture until the hydration process is complete and concrete attains the requisite strength.

The curing method and time primarily depend on structure type, site conditions, and ingredient parameters. Some of the Types of concrete curing methods adopted in constructions sites are as follows.

- Maintaining a water layer over the concrete surfaces (water curing)

- Reducing the loss of water from concrete

- Accelerating the initial strength gain

Let us go through these three basic concepts and onsite concrete curing methods adopted for each of these criteria.

Maintaining water over the concrete surfaces -Concrete Water Curing Techniques

Maintaining water over concrete surfaces or water curing is the most popular and conventional method of concrete water curing techniques. The methods of curing depends on the type of structure basically. Let us go through the water curing techniques adopted in construction sites .

- Ponding

- Spraying and fogging

- Saturated or wet coverings

- Immersion curing

Ponding

Ponding is the method of wetting the concrete surface by creating a temporary containment area around the concrete.

The ponding method is one of the very well-known and widely adopted concrete water curing technique. This method is possible only on horizontal or flat structures and is best suited for curing concrete slabs.

Small bunds of clay or lean cement sand are placed over the concrete surface. Water is filled in the bunds, refilled, and maintained as and when the level goes down.

This method is very efficient but requires a huge amount of water. The ponding method of curing is not preferred for large areas and areas where water is scarce.

Spraying and fogging method of curing

Spraying and fogging are conventional water curing methods for horizontal and vertical concrete surfaces. These methods are very effective and efficient in supplying additional moisture during hot weather. The spraying and fogging methods help in reducing the temperature of the concrete.

Spraying is a manual method of simply spraying water over the concrete surface. Even though the spraying method is effective, it tends to waste a lot of water.

Fogging is applicable for areas where the temperature is above freezing point and with low humidity. This process raises the humidity higher than curing concrete by spraying a fine mist of water regularly across the concrete surface. Fogging, or fog spraying is effective in reducing the chances of plastic shrinkage cracking in mixes.

Saturated or wet coverings

In this method of curing, saturated or wet coverings are placed over the hardened concrete. The wet covering material includes hessian cloths, cotton mats,moisture-retaining fabrics, etc. Vertical and inclined structures like columns, beams, sloped roofs, etc are cured in this method.

Immersion curing

Immersion method of curing is for curing concrete specimens.

Reducing Water loss from concrete- Methods of concrete curing

This concept of curing is by reducing the moisture loss from the concrete surface by wrapping it with an impermeable membrane or plastic sheets. This method is the most practical and efficient way to cure concrete nowadays and is a much-needed option for areas where there is water scarcity. The common methods are..

- Membrane Curing of Concrete

- Covering concrete with impervious sheets or plastic sheets

Membrane Curing of Concrete

The application of curing compounds is through spraying or painting directly on the concrete surface. The compound dries and forms an impermeable membrane that retards or reduces the moisture loss from the concrete. The membrane curing method is a flexible and easy method of curing.

Engineers apply curing compounds once the concrete has hardened but still contains surface moisture. They complete the application before the water evaporates fully from the concrete. The membrane curing may not produce desired results, if applied after the water evaporates. Ensure uniform thickness and coverage during the application process.

Curing compounds are available in acrylic-based and water-based forms.

The curing compound should comply with ASTM C3094 or ASTM C13155.

Always go through the manufacture specification before application of curing compounds.

Covering with plastic sheets

Engineers apply impervious paper and plastic sheets on thoroughly wetted concrete in this method. The concrete surface should be hard enough to take the possible damages while placing the sheets.

Accelerating strength gain method of concrete curing

Engineers accelerate strength gain by applying heat or additional moisture, speeding up the early hardening of concrete and mortars through controlled steam and humidity. The following curing methods use this technique.

Concrete Steam Curing

The steam curing method uses water vapor or steam for curing the concrete elements. This method of curing is for cold weather conditions where the concrete needs accelerated early strength gain and additional heat for hydration. Prestressing and precast factories use the steam curing method for early strength gain of components. The early strength gain can enable rapid removal and reuse of forms.

The steam curing is done in two ways

- live (or low pressure) steam at atmospheric pressure

- high-pressure steam curing in autoclaves.

Steam curing of concrete at atmospheric pressure

Steam curing allows increased production due to rapid repetition and reuse of molds/forms in precast yards.

Engineers keep the steam temperature at around 140°F or lower for live steam at atmospheric pressure until the concrete reaches the desired strength. By maintaining an optimum temperature, they can achieve the 28-day strength of normally water-cured concrete in just 3 days using the steam curing method.

High-pressure steam curing

Engineers carry out high-pressure steam curing in a closed chamber at elevated temperature and pressure. They refer to this process as “Autoclaving.” They maintain temperatures between 325° and 375°F and pressures around 80 to 170 psi. Engineers use this method to manufacture precast components, cellular concrete products, cellular blocks, precast panels, and autoclaved aerated concrete (AAC) blocks.

The main advantage of a high-pressure steam curing system is the capability of attaining 28 days of strength of normally cured concrete in 24 hours.

High-pressure steam cured concrete got less creep and shrinkage and better sulfate resistance. There will not be any efflorescence and moisture content after curing.

Heating coils

Heating coils are usually used as embedded elements near the surface of concrete elements. Their purpose is to protect concrete from freezing during cold weather concreting.

Key Takeaways

- Methods of concrete curing are essential for strength and durability, requiring controlled moisture and temperature.

- Water curing is the most common method, employing techniques like ponding, spraying, and fogging.

- Membrane curing is preferred in water-scarce areas, using impermeable sheets to minimize evaporation.

- Steam curing accelerates early strength gain, particularly in cold weather, using live or high-pressure steam.

- The choice of curing method depends on structure type, site conditions, and climatic factors.

Conclusion

Selecting the right Methods of Concrete Curing on site is essential to ensure concrete develops its intended strength and durability. Engineers choose different Types of Concrete Curing depending on weather conditions, structural exposure, and project requirements. Engineers use Concrete Water Curing Techniques such as ponding, spraying, and fogging to supply continuous moisture for most slabs and structural elements and prevent early drying. When water is limited or evaporation is high, they apply Membrane Curing of Concrete to retain internal moisture effectively. In colder climates or when faster formwork removal is needed, Steam Curing Concrete accelerates hydration and early strength gain. By applying the correct On-Site Concrete Curing Methods, construction teams can minimize thermal cracking, improve service life, and deliver high-quality structures that perform reliably throughout their lifespan.

One thought on “Methods of concrete curing – Key Techniques Explained”

Comments are closed.