Types of pile foundations offer essential solutions in civil engineering and construction projects. These foundations are specifically employed when the subsoil stratum is unable to bear the imposed loads from the structure. Pile foundations excel at transferring loads to deeper and more reliable strata capable of withstanding the forces involved. Generally, they outperform open foundations, which primarily distribute loads horizontally, by efficiently transferring loads vertically into the ground. Common types of pile foundations include driven piles, bored piles, and auger cast piles, each tailored to suit different soil conditions and project requirements. The selection of the appropriate pile foundation type is crucial to ensure structural integrity and stability in diverse construction scenarios.

Types of Deep Foundations

Foundations can be broadly categorized as shallow foundations or deep foundations. Shallow foundations are suitable when structure loads are relatively low compared to the bearing capacity of surface soils. In contrast, deep foundations are necessary when surface soils lack sufficient bearing capacity, requiring load transfer to deeper layers with higher capacity.

Deep foundations are defined by their substantial depth-to-width ratio, indicating a greater depth compared to their horizontal extent. This distinction emphasizes their ability to penetrate deeper layers of the soil to achieve the necessary load-bearing capacity. As a result, deep foundations effectively transfer structural loads vertically into the ground. Pile foundations, among other classifications, fall under the category of deep foundations, illustrating their prominent role in supporting structures with greater depth requirements. The types of deep foundations are as follows.

- Basement foundations

- Caissons Foundation

- Hollow Box Foundation or Buoyancy foundations

- Drilled shaft foundations

- Pile foundations

For more details about Deep foundations read the following articles from vincivilworld.

This article is about the types of pile foundations and their classifications based on materials, methods of installation and functions.

Related posts about deep foundations and shallow foundation types.

What are Pile Foundations?

Pile foundations are comprised of elongated and slender structural elements, typically crafted from materials like steel, concrete, or other appropriate substances. These foundations are specifically engineered to facilitate efficient load transfer, ensuring that the vertical loads are effectively transmitted from the structure through the pile and into the underlying soil or rock layers.

Pile foundations – When and where to use them?

We can use a pile foundation when

- When the groundwater table is very high and other types of open foundations necessitate extensive dewatering using the well point or deep bore well system, which is both expensive and impractical.

- When there is a heavy and non-uniform distribution of loads from the superstructure, it causes unequal settlements in open foundations.

- When the low soil bearing capacity and site constraints make shallow foundation design very conservative and uneconomical.

- When the permissible limit for soil settlement is exceeded while designing a shallow foundation.

- When the presence of any underground systems, rivers, or canals nearby increases the probability of soil washing or scouring away from the foundation sides.

- When any type of soil excavation is impossible due to very poor soil strata.

- Expansive Soil Conditions: Pile foundations are suitable for areas with expansive soils that undergo significant volume changes due to moisture variations. By reaching deeper layers unaffected by moisture changes, pile foundations mitigate potential soil movement and associated structural issues.

- Waterlogged or Marine Environments: Pile foundations are utilized in waterlogged or marine environments, such as coastal regions or waterfront structures. Piles driven into the ground or underwater provide stability against water forces and ensure structural integrity.

- Sloping Sites: In areas with significant slopes, pile foundations offer a solution to maintain stability and levelness. Piles can be installed at different depths to compensate for variations in the ground profile, providing a level base for construction.

Types of pile foundations

The types of pile foundations are broadly classified based on the following parameters

- Pile foundation types based on the Load transfer mechanism

- Pile foundation types based on the Method of installation

- Types of pile foundations based on the Materials used.

- Pile types based on specific applications or design functions.

Here is a small video based on the types of piles based on above classifications.

Types of pile foundations : Short video

Types of Pile foundations- Based on the Load transfer mechanism

- End Bearing piles

- Friction piles

- Friction cum bearing piles

End Bearing Pile types

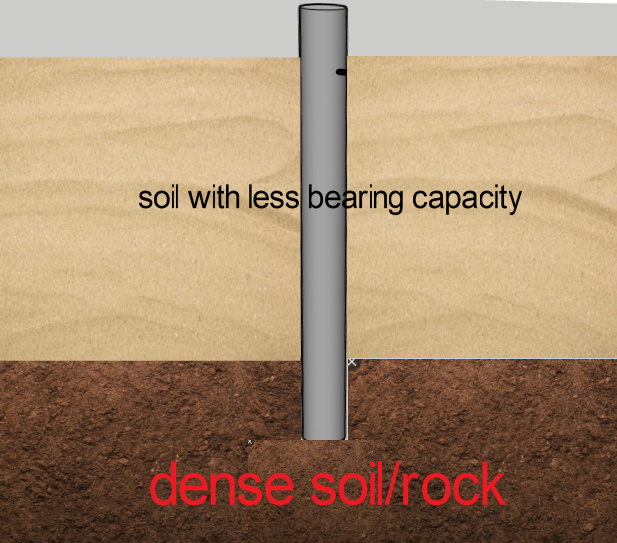

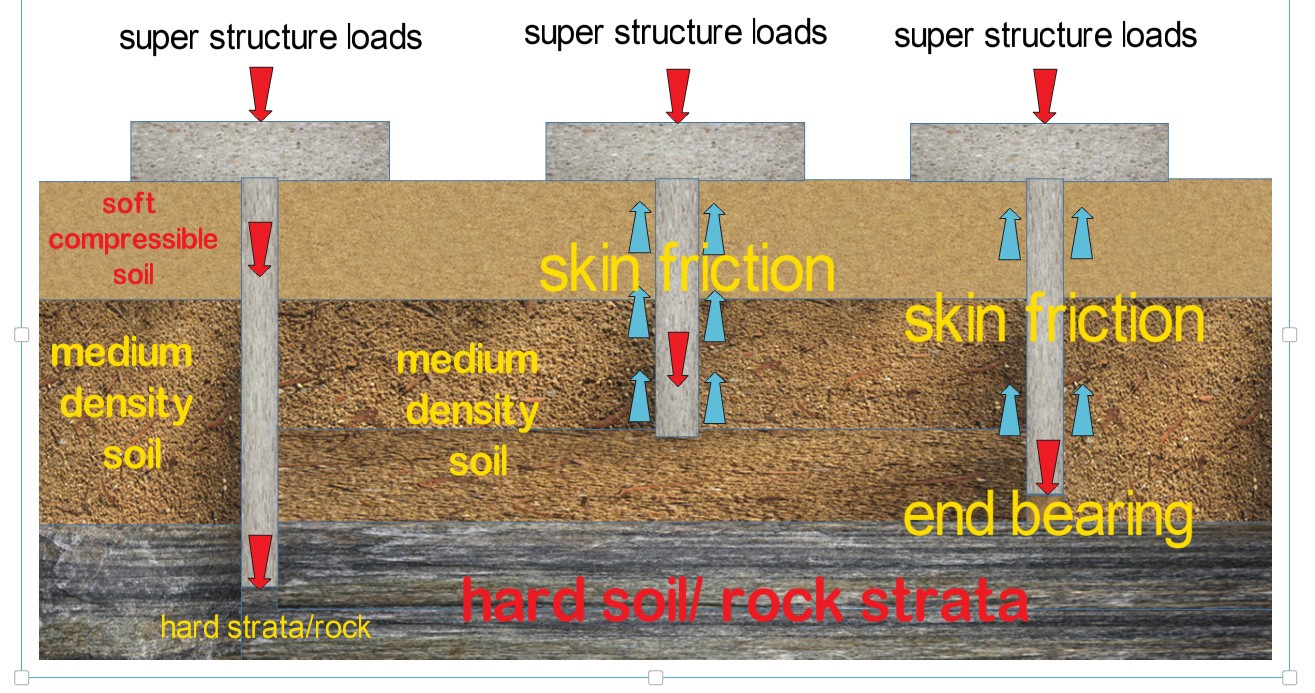

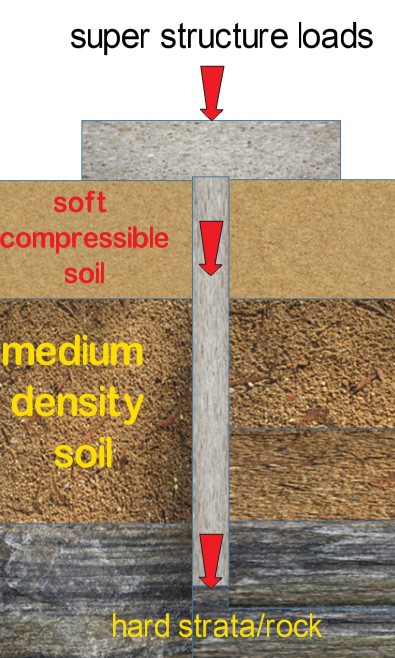

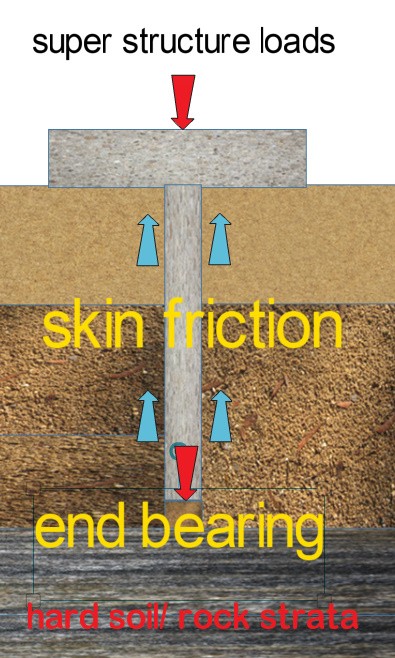

A bearing pile is a slender member/column that transmits all loads from the superstructure vertically. In this case, transmission occurs through a lower density weak layer of soil to denser strata much below ground capable of negotiating the loads. Moreover, the pile functions as a component of a column that transfers loads to the bearing strata.

Friction Piles

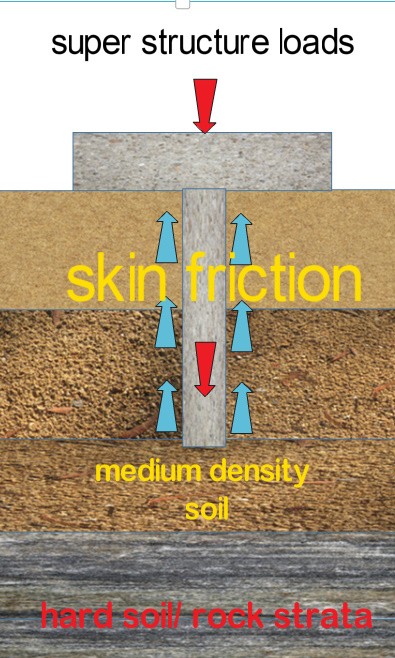

When a suitable strata for negotiating the loads are present at a very deeper location, and installing piles to that depth is not economically viable, friction type of pile foundations are used. These piles make use of the skin friction and shear stresses present along the pile’s surface. Load transfer takes place due to frictional resistance between the pile surface and the surrounding soil. The complete surface area of piles is engaged in the load transfer process. The pile’s capacity to support a specific load increases with the embedded length. The load carrying capacity of a pile is directly proportional to its length.

Friction cum End Bearing type of piles

These piles negotiate loads through the combined action of end bearing and skin friction. Friction cum end bearing piles can be terminated at an intermediate medium strata without having to move up to a hard strata. These piles are preferred and regarded as the most cost-effective type of pile foundation.

Pile foundation types – Based on Method of installation

The execution of piling is done in two methods

- Driven or Displacement Method

- Bored or Replacement Method

Driven or Displacement Type of Pile Foundations

Driven piles, also known as displacement piles, are driven into the ground or sand to cause lateral soil displacement. Displacement piles are primarily designed to be installed without the removal of soil. Special equipment is used to drive the piles and displace soil laterally. In some sitovertions, these heaps are preferred to bored piles.

Types of Pile Foundations – You tube video

Bored Or Replacement types of Piles

In this type of pile foundation, the requisite diameter bores are formed and filled with RCC. Depending on the collapsible nature of the soil, it can be either cased or uncased.

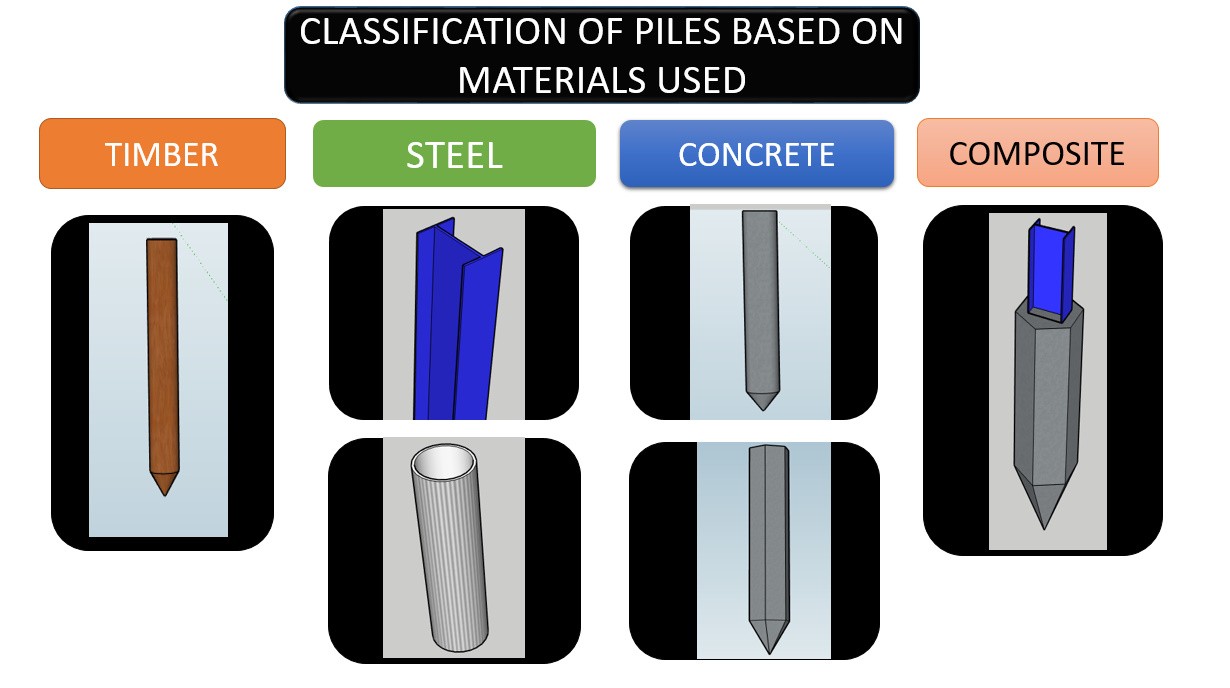

Types of pile foundations based on the Materials used.

- Timber piles

- Steel piles

- Concrete piles

- Composite piles

Let us describe about each one in detail.

Timber pile types

Sharpened logs from trees including sal, teak, deodar, and babul are used to make the timber piles. These pile foundations are used in water and are more resistant to sea water than other pile foundations. These piles into the ground and are basically friction piles. The timber pile length varies between 20 and 25 metres and is designed to support a load of around 20 tonnes.

Advantages of timber pile foundation

- Timber piles come in a variety of sizes and are mpilesaffordable than other types of pile.

- It is simple to install and may be customised to any size needed.

- Timber piles are more reliable in marine construction.

- Timber piles do not deteriorate even when submerged in water for a prolonged period of time.

Disadvantages of timber piles

- Straight and long timber piles are difficult to locate.

- Timber piles may not be able to traverse all strata.

- Pile driving is challenging in hard and dense strata.

- Timber piles can only be used as friction piles, not end-bearing piles.

- Splicing a timber pile is difficult.

- Timber piles must be treated with preservatives to avoid deterioration.

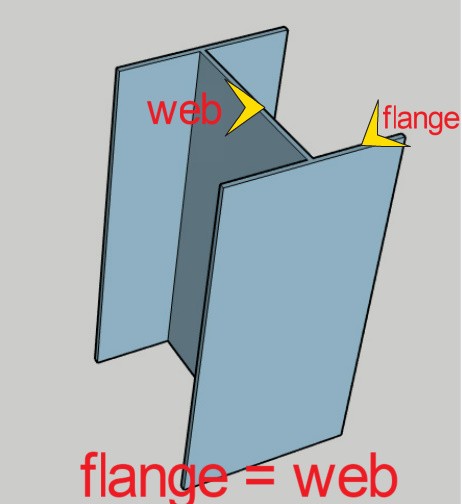

Steel Piles

Steel piles can be hollow pipes or H-sections (See Fig.). Their ideal length for utilisation is between 20 and 40 metres. The size can be up to 600 mm dia pipes and can also be done using HP sections with the same flange and web width as shown in the figure. These piles are generally intended to be end-bearing piles. These piles can be driven open-ended or closed-ended wherein Concrete shall be poured into the closed-ended pile.

Advantages of steel piles

- Steel piles are fairly simple to install. Because of their smaller cross-sectional area, they can penetrate through any sort of soil layer with minimal soil displacement.

- Compared to other types of piles, splicing steel piles is simple and can be done at any depth.

- Steel piles’ penetrating properties allow them to go deeper and bear higher loads than other pile types.

Disadvantages of steel piles

- Steel piles are prone to corrosion must be coated with anticorrosive coatings before driving.

- The H sections often distort when they come into contact with a hard stratum, and occasionally during driving the pile the verticality can be lost.

- Steel piles are extremely expensive.

Concrete Pile

Due to its adaptable design and simplicity of manufacture, concrete is the most popular material used to construct piles. However, different types of concrete piles are available to cater every need.

Types of concrete Pile Foundations

- Precast Concrete Pile

- PrestressedConcrete Pile

- Cast- in – situ Concrete Pile

- Composite Concrete pile

Precast Concrete Pile

Conventional RCC is used for precast piles. In this case, piles are cast in a fabrication yard and transported to the site for erection. Precast piles are either square or circular. Rectangular or square piles are cast horizontally, while round piles are cast vertically. Precast piles are designed to withstand the loads and stresses that arise during lifting, transporting, and driving.

Prestressed Concrete pile

When the sizes of the precast piles exceed a particular limit, prestressed concrete piles are preferred. Prestressing can substantially reduce pile size, making it much easier to handle, transport, and construct. The process of prestressing involves stretching the tendons and pouring concrete while keeping them stretched. The tendons are released once the concrete has attained its full strength. In the process of regaining their shape, the released tendons create compressive stresses in the member.

Prestressing transforms the pile into a high load carrying member that can withstand stresses, due to the impact loads generated during driving, the uplift pressures, and the combined moments These piles can be employed at an ideal design depth of 25-35 metres.

CAST IN SITU CONCRETE PILES

Cast in situ piles are constructed by drilling a bore hole to the desired depth and then filling it with Reinforced cement concrete. Bore holes can be generated by removing the earth with rotary drilling equipment or hydraulic rigs. Prior to drilling, casings are driven into the locations of the bores. During the concreting process, the casing will be gradually removed, or it may occasionally be left in the bore as a permanent casing.

Advantages of Cast-in-Place Concrete Piles

- Cast in situ piles is more flexible and easier to execute than driven piles and other types of piles.

- The reinforcement cages are lightweight in weight and easy to handle. The rebar cages are fabricated using simple and standard tools.

- There is no risk of breaking during the installation stage.

- Additional substitution piles can be created if there is a problem with the pile that causes the customer to abandon it.

Disadvantages of Cast-in-situ Concrete Piles

- Installation necessitates careful supervision and quality control. Because it costs money and time to execute a replacement pile when a pile is abandoned.

- Cast-in situ piles generate a significant amount of pile muck ( mix of bentonite and soil). Moreover, the pile muck must be removed and disposed of according to environmental regulations.

- The pile head chipping also generates a large amount of concrete debris, that needs to be disposed of.

- Needs room for rig movement, crane movement, material storage, and bentonite tank storage. d) Underwater flow may cause the piles to collapse.

Composite pile

A composite pile is made up of two or more sections of different materials or pile types. The top portion shall be made of concrete, while the remaining portions shall be made of steel or wood. Mostly, these piles are used for specialized applications.

Classification of pile foundations based on specific applications or design functions.

Batter piles

Batter piles are pile types that are driven at an inclination to resist large horizontal or inclined forces. Since offshore constructions are vulnerable to overturning moments from wind, waves, and ship collisions, batter piles are frequently employed to support offshore structures, towers, and bridges. A combination of vertical and batter piles is deployed to transfer the overturning moment to compression and tension forces.

Fender piles

A fender pile is an upright, generally freestanding pile sunk into the seabed or riverbed at a berth to protect the dock wall or wharf from the impact of vessels. Fender piles protect the concrete deck or other waterfront structures from abrasion or impact caused by ships or barges when they are tied up at the deck. Mostly, these piles are usually made of timber.

Anchor piles

Tension piles, also known as uplift piles or anchor piles, are a type of pile foundation used to resist uplift forces that would otherwise cause the pile foundation to be pulled from the earth. Tall constructions, in particular, such as chimneys, jetties, and transmission towers, can be vulnerable to strong wind loads subjecting to overturning moments. Likewise, hydrostatic pressure, seismic activity, or overturning moments can all cause uplift forces. However, the generated compressive and tensile forces must be transmitted to the ground along the pile’s length.

Sheet piles

To support excavations and retain earth, sheet piles-sections of sheet material with interlocking edges are driven into the ground. Sheet piles are usually composed of steel, but they can also be made of wood or reinforced concrete. Mostly, these piles are often used for retaining walls, land reclamation, underground constructions such as car parks and basements, in marine settings for riverbank protection, sea walls, cofferdams, and so on.

4 comments

Comments are closed.