Sheet piling is a widely used construction technique that involves the installation of interlocking sheet piles to form continuous walls. These walls provide essential support for earth retention and excavation. This makes sheet piling crucial in projects like foundations, retaining walls, and marine structures. A sheet pile foundation works particularly well in areas with weak soil or high water tables. It provides stability and durability in challenging conditions.

The process of sheet piling involves driving prefabricated steel, vinyl, or timber sheet piles into the ground. This process creates a sturdy barrier against soil movement and water ingress. Sheet piling is known for its versatility. It is used in both temporary and permanent applications. Examples include excavation pits, seawalls, and flood protection systems.

This article explores the materials, methods, and advantages of sheet piling, highlighting its importance in modern construction and infrastructure development.

Table of contents

Sheet piling method

Sheet piles serve both temporary and permanent applications, with permanent steel sheet pile foundations designed for long-term service. Typically, sheet piling is installed using vibratory hammers. When the soil is dense or hard, an impact hammer is used instead. Hot-rolling and cold-forming are the two primary methods for manufacturing sheet piles. Hot-rolled piles are produced at high temperatures. This process makes the interlocks stronger and more durable.

Sheet piles are driven into the ground with an impact hammer or vibratory driver. They are connected through various interlocking systems. These include tongue-and-groove, hook-and-grip, or clutch-bolt connections. Once installed, the sheet piling forms a continuous barrier. It resists lateral pressure from soil or water. This helps to prevent soil erosion, landslides, and other soil failures.

The following are the common methods adopted for sheet piling works

Vibratory Hammer Method

The vibratory hammer method involves using a vibrating tool to drive sheet piles into the ground. The vibrations reduce the soil resistance, allowing the piles to penetrate more easily, especially in cohesive, sandy, or gravelly soils. This method is effective in speeding up the installation process. It is commonly used for relatively soft soils where high soil resistance isn’t an issue.

Impact Hammer Method

In the impact hammer method, an impact hammer delivers a powerful strike to the top of the sheet pile. This force drives it into dense or hard soils. The force generated by the hammer helps break through tough, compacted soil layers. This method is ideal for soil types that are difficult to penetrate with vibration-based techniques. Examples include stiff clays or rocky ground.

Press-In Method

The press-in method uses hydraulic or mechanical presses to push sheet piles gradually into the ground. This method does not produce noise or vibrations. It is suitable for areas with strict regulations on noise levels. It’s also suitable for working near sensitive structures. The press-in method allows for controlled installation and is ideal for projects that require minimal disruption to the surrounding environment.

Pitch and Drive Method

The pitch and drive method involves an initial pitching of the sheet piles into the ground. Then, they are driven to the desired depth using an impact hammer. This method offers flexibility, as it allows for easy adjustments during installation. It is versatile, making it suitable for various soil conditions and construction needs, particularly in confined spaces or areas with limited access.

Each of these methods has specific applications depending on the soil type, project requirements, and site conditions. Proper equipment, experienced operators, and careful planning are essential for successful sheet piling installation.

Advantages of Sheet pile foundations

Sheet piling offers numerous benefits in construction projects, making it a preferred choice for various applications. Key advantages include:

- High Resistance to Driving Stresses: Sheet piles withstand significant driving stresses during installation, ensuring structural integrity.

- Lightweight and Easy Handling: Their lightweight nature facilitates easier handling and installation, reducing labor and equipment costs.

- Reusability and Recyclability: Builders reuse sheet piles in multiple projects and recycle them, promoting sustainability and cost-effectiveness.

- Cost-Effectiveness: Steel sheet piling is often more cost-effective than concrete piling, reducing overall project expenses.

- Minimal Environmental Impact: The installation process is less disruptive to the surrounding environment, preserving adjacent landscapes and structures.

These advantages make sheet piling a versatile and efficient solution for earth retention, excavation support, and various other construction needs.

Sheet piling types

Sheet piles are essential in construction for earth retention and excavation support. They come in various materials and profiles, each suited to specific applications. Sheet piles are broadly classified as follows based on the material used for driving.

- Steel sheet pile

- Vinyl sheet pile

- Wooden sheet pile

- Precast Concrete sheet pile

- Composite sheet piles

- Cellular sheet pile

- Cold-formed sheet pile

Steel Sheet piles

Steel sheet piles are long, thin sections of steel. They are driven into the ground to create a sheet pile retaining wall or barrier. They are one of the most popular materials for sheet piling works . This popularity is due to their ability to be lengthened by welding or bolting. They offer excellent water tightness and high resistance to driving stresses. Steel sheet piles are very commonly used in civil engineering projects. They provide structural support for deep excavations, foundations, highways, bridges, and more.

Manufacturers primarily make these piles from hot-rolled steel in various shapes and sizes. Workers link them together to form a continuous, robust barrier that resists both soil and water pressure. In sheet piling works, engineers design steel sheet piles to bear heavy loads while providing structural stability. Corrosion prevention techniques, including coatings and cathodic protection, significantly enhance the durability and longevity of steel sheet piles.

Steel sheet piles are perfect for sheet pile foundation work. They are especially suited for deep excavations. These piles offer exceptional lateral stress resistance. They are quick and easy to install, making them an efficient solution. Additionally, steel sheet piles are recyclable, making them an eco-friendly option for temporary structures.

Overall, steel sheet piles are versatile, durable, and cost-effective solutions for various civil engineering and construction projects. There are four main types of steel sheet piles. These are Normal sections, Straight web sections, Box sections, and Composite sections. Each type offers unique advantages for specific applications.

Common Types of Steel Sheet Piles

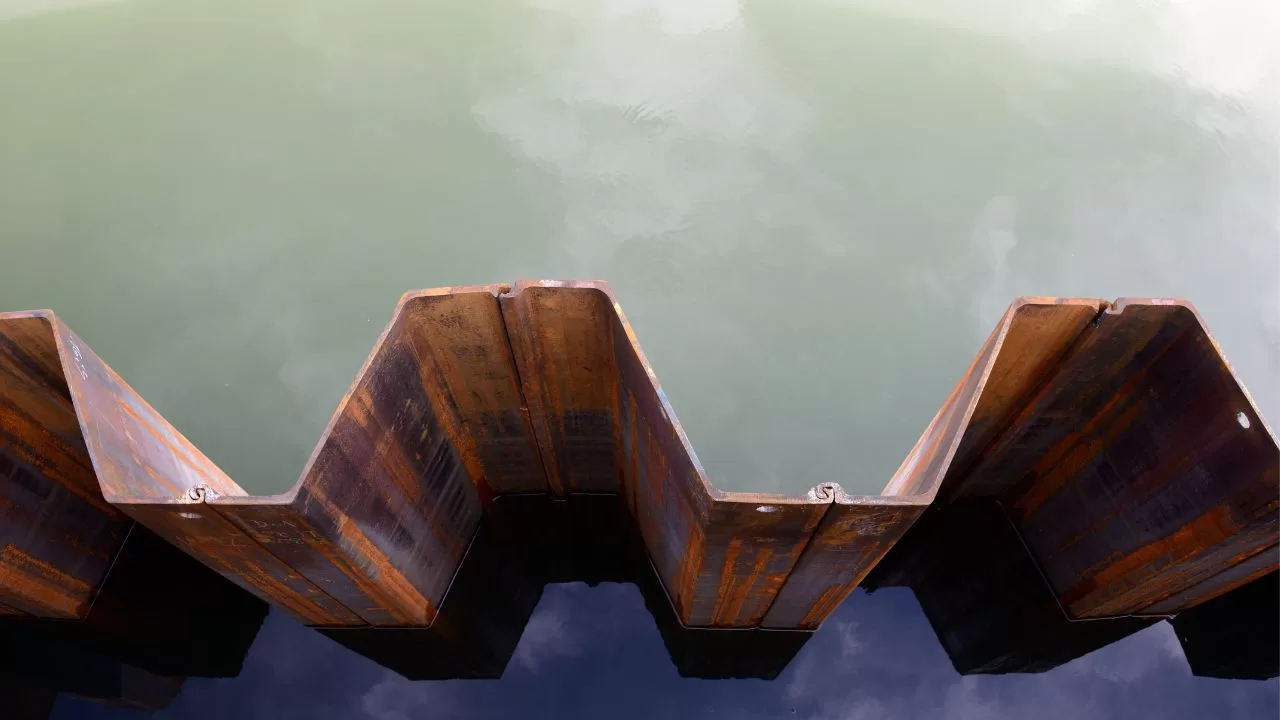

- Z-Type Sheet Piles: These piles have a Z-shaped cross-section, offering high bending strength and interlock efficiency. Engineers widely use them in retaining and floodwall applications where bending strength is crucial.

- U-Type Sheet Piles: These piles feature a U-shaped cross-section. Contractors commonly use them for temporary excavations and utilize them for permanent retaining structures with higher retained soil heights.

- Straight Web Sections: Flat profile sections used primarily for constructing temporary cellular cofferdams. Contractors also employ them in permanent structures such as breakwaters, earth containment sites, and piers.

- OZ-Type Sheet Piles: This consists of a steel tube combined with a Z-type sheet pile. They are used for soil retention and load transfer. Their interlocks are located on the neutral axis, providing strong bending resistance.

Vinyl sheet pile

A vinyl sheet pile is a form of plastic sheet pile with various applications in civil engineering.Contractors use vinyl sheet pile in construction projects for seawalls, bulkheads, flood walls, and retaining walls. Manufacturers primarily make vinyl sheet pile from polyvinyl chloride (PVC). PVC is a lightweight and long-lasting polymer. It resists corrosion, chemicals, and weathering. Vinyl sheet pile requires minimal maintenance. It is simple to install. It also offers long-term durability. For these reasons, vinyl sheet pile is becoming more and more common in construction projects. Vinyl sheet pile does not require frequent maintenance or coating. This is unlike traditional materials such as wood, steel, or concrete. It makes vinyl sheet pile a more cost-effective alternative in the long run.

Vinyl sheet piling works are also environmentally friendly. It is reusable and does not leak dangerous chemicals into the soil or water. Because of its lightweight qualities, it is simple to transport and install, necessitating minimal use of heavy machinery and labour. Overall, vinyl sheet pile is a versatile and cost-effective solution for a variety of construction and civil engineering projects. Its durability, low maintenance requirements, and environmental benefits make it an appealing choice for contractors and engineers.

An effective alternative to steel sheet piling for bulkheads, seawalls and cutoff walls. They are also superior to alternative materials like concrete and wood. The main advantage of vinyl sheet piles is the superior corrosion resistance when exposed to seawater, where no oxidation occurs.

Vinyl sheet piles are lightweight. They resist corrosion and chemical damage. These properties make them suitable for projects with minimal environmental concern.

Wooden sheet pile

Wooden sheet piling works consist of vertical wooden planks. They interlock to form a continuous barrier. These are commonly used in civil engineering for temporary support structures. They are particularly effective for braced sheeting and temporary structures. In coastal construction, they help prevent soil erosion and maintain the integrity of embankments. The interlocking design ensures stability and resistance to lateral pressures.Engineers treat wooden sheet piles with preservatives to enhance their durability and prevent decay, especially in moist environments. This treatment extends their lifespan and maintains structural integrity. Engineers use wooden sheet piles to provide a natural aesthetic. They typically use them in situations where soil height exceeds water level. This method effectively offers shore protection.

However, these piles offer less suitability for heavy-duty applications compared to steel or concrete alternatives.

Features of wooden piles

Timber sheet piling works are not suitable in strata that contain gravel and boulders. Hardwood sheet piles are ideal for shallow excavations and we frequently utilise them in building projects where noise and vibration are a concern. They are lightweight and easy to handle, making them a popular choice for jobs requiring speedy installation. In comparison to other retaining wall materials, wooden sheet piles are also more affordable. Yet, there are significant drawbacks to using hardwood sheet piles. They are not as robust as steel or concrete sheet piles and require frequent maintenance to prevent rot and insect infestation. Wooden sheet piling works are prone to warping and deformation if exposed to dampness for a lengthy period of time.

High water tables or soil salinity might accelerate the decomposition of hardwood sheet piles, making them unsuitable for use in such conditions.Overall, hardwood sheet piling works are an efficient and environmentally friendly option for small-scale building projects and temporary retaining walls. Yet, their durability and susceptibility to deterioration and warping make them unsuitable for long-term or large-scale applications.

Concrete sheet pile

Concrete sheet piles are retaining walls constructed from precast reinforced concrete sections. We frequently employ them in civil engineering and building projects with a requirement for long-term retaining structures.

We must handle and drive the piles carefully, and provide the necessary reinforcement. The most common application of Concrete sheet pile is in deep excavations where soil conditions are unfavorable and we require lateral support. They are impermeable and can withstand hydrostatic pressure, making them excellent for usage in places with high water tables. We provide a capping to the heads of the piles by casting a capping beam, while we cut the toes with an oblique face to make driving and interlocking easier. They are relatively heavy and thick, and while driving, they displace significant amounts of the earth.

The driving resistance rises as a result of the considerable volume displacement. Concrete sheet piles are also resistant to weathering, corrosion, and erosion, making them a durable solution under extreme conditions. Concrete sheet piles are available in a range of dimensions and we can interlock them to create a continuous wall. We can place them in a variety of ways, including driving, vibrating, and pushing. The method of installation depends on the accessibility to the site, the depth of the installation, the state of the soil etc.

Concrete sheet piles are a strong and long-lasting alternative, but their installation may be more costly and time-consuming than that of other retaining wall materials. However, installing them requires large machinery, which can be difficult in places with restricted access or space. Overall, concrete sheet piles are a viable option for permanent retaining walls in deep excavations and severe soil conditions. They are a preferred option for projects involving coastal protection and flood control due to their strength and resistance to water and erosion.

Aluminium sheet piles

Aluminium sheet piles are lightweight, strong, and corrosion-resistant, making them an ideal choice for projects that require a lightweight and durable material.Aluminum sheet piles are lightweight, corrosion-resistant barriers used in civil engineering for applications such as seawalls, bulkheads, and water control structures. They offer a high strength-to-weight ratio, facilitating easy handling and installation. Aluminum’s resistance to corrosion from air, water, extreme temperatures, and chemicals makes it suitable for harsh marine environments. Additionally, aluminum sheet piles are recyclable, contributing to sustainable construction practices. However, they are generally more expensive than other materials like steel or vinyl.

Proper drainage is essential to prevent hydrostatic pressure buildup behind aluminum sheet piling walls, which can lead to structural issues

Composite sheet piles

Composite Sheet Piles combine the properties of both steel and synthetic materials like vinyl, polymer, or concrete. These types of piles provide the strength of steel along with the corrosion resistance and environmental advantages of synthetic materials. Engineers widely use them in marine, coastal, and waterfront construction projects, offering superior durability and long-term performance.They are typically lighter than traditional steel piles, making them easier to handle and install. The composite nature also helps in reducing maintenance costs due to better resistance to rust, corrosion, and other environmental factors. Engineers commonly use these piles for construction in aggressive environments, such as saltwater areas, where traditional materials may degrade quickly.

Cellular sheet pile

Construction teams use cellular sheet pile walls, or circular cell cofferdams, to isolate areas for excavation and construction, particularly in marine environments. This technique involves arranging sheet piles in a circular pattern to create interconnected cells. They backfill these cells with compacted granular material or concrete, forming a barrier that separates the work zone from adjacent water bodies. The structure achieves stability through the combined action of the soil fill and interlocking steel piling. Engineers frequently employ cellular sheet pile walls in constructing dams, locks, wharfs, bridge piers, and other marine structures.

We usually design Cellular sheet pile with hollow sections that allow for increased strength and load-bearing capacity. They find application in projects that requires a high degree of lateral support.

Cold-formed sheet piles

Cold-formed sheet piles are made by bending steel sheets into a desired shape. They find application in projects requiring lower strength and load-bearing capacity.

Sheet piles – Applications

Sheet piling find frequent utilization in the following construction projects

Retaining walls

Sheet piles help to construct retaining walls that hold back soil or water while also providing lateral support for excavations.

Coastal protection

Sheet piling can protect coastal areas from erosion, waves, and storm surges.Builders also use them to construct breakwaters and jetties.

Cofferdams

We use Sheet piles to build cofferdams, which are transient obstructions in water to facilitate the construction of piers, bridges, or other water-based constructions.

Underground structures

We use Sheet piles to construct underground constructions such as basements or underground parking garages. They support the lateral structure and restrict soil or water intrusion.

Sheet piles have various advantages, including their versatility, ease of installation, and durability. Moreover, they offer an affordable option for projects that need lateral earth support. However, adequate design and installation are essential for guaranteeing the sheet pile wall’s stability and safety.

Conclusion

Each type of sheet pile has its own advantages and disadvantages. The choice of material and design depends on the specific requirements of the project. Designers and installers must ensure the stability and safety of the sheet pile wall, and engineers recommend consulting an experienced professional before selecting a specific type of sheet pile for a project.