Shrinkage of concrete refers to the reduction in its volume over time, primarily due to moisture loss and chemical reactions during hydration. This phenomenon can lead to shrinkage cracking of concrete, compromising structural integrity and durability. Understanding what shrinkage of concrete is involves recognizing its various forms, such as drying shrinkage, autogenous shrinkage, and thermal shrinkage. Drying shrinkage occurs as moisture evaporates from the hardened concrete. Autogenous shrinkage results from internal chemical reactions during the hydration process. Thermal shrinkage happens due to temperature variations affecting the concrete mass. Factors influencing shrinkage include water-cement ratio, environmental conditions, and the concrete mix design. Mitigating shrinkage involves proper curing practices. It includes using shrinkage-reducing admixtures. Another method is optimizing mix proportions to minimize water content, thereby reducing the potential for shrinkage cracking.

Concrete shrinkage is a critical phenomenon in the construction industry. It refers to the reduction in volume of concrete as it undergoes hydration and drying. This dimensional change can lead to cracking, compromising the structural integrity and durability of concrete structures. Engineers, contractors, and stakeholders must understand the causes, types, and preventive measures of concrete shrinkage. This knowledge ensures the longevity and performance of concrete infrastructures. This article is about the types, causes and effects of Concrete shrinkage

Table of contents

What is shrinkage of concrete ?

Concrete, a composite material composed of cement, aggregates, water, and admixtures, is the backbone of modern construction. Its versatility, strength, and durability make it the material of choice for various structural applications. However, one inherent characteristic of concrete is its tendency to shrink during the curing process. This shrinkage, if not properly managed, can lead to cracks, reducing the lifespan and safety of structures. Therefore, a comprehensive understanding of concrete shrinkage is paramount for effective construction practices.

Shrinkage in concrete is the decrease in its volume over time. This occurs due to the loss of moisture and the chemical reactions during cement hydration. This volumetric reduction can induce tensile stresses within the concrete matrix. It leads to the formation of cracks, especially when the material is restrained. Cracks are also likely when shrinkage occurs unevenly. The primary factors influencing concrete shrinkage include the water-cement ratio, environmental conditions, and the properties of the constituent materials.

Types of Concrete Shrinkage

Concrete shrinkage is a natural phenomenon that affects the durability and structural integrity of concrete over time. It occurs due to moisture loss, chemical reactions, or temperature changes, leading to volume reduction and potential cracking. Understanding the different types of shrinkage is crucial. These types include plastic, drying, autogenous, thermal, and carbonation shrinkage. This knowledge helps in selecting appropriate construction techniques. These techniques minimize shrinkage-related issues and improve concrete performance.

Plastic Shrinkage

Plastic shrinkage occurs within the first few hours after concrete placement while it is still in a plastic state. It happens due to rapid evaporation of surface moisture, especially in hot, dry, or windy conditions. This leads to surface tension, causing shrinkage cracks to form. These cracks are often random, shallow, and irregular, primarily appearing on slabs and pavements. Preventing plastic shrinkage involves proper curing, windbreaks, shading, and using evaporation retarders to maintain surface moisture and reduce crack formation.

Drying Shrinkage

Drying shrinkage occurs as hardened concrete loses moisture to the surrounding environment. This process can last months or even years, depending on humidity levels and concrete properties. As water evaporates, capillary tension develops, causing the concrete to contract, leading to shrinkage cracks. These cracks can compromise durability and structural integrity. To reduce drying shrinkage, engineers use shrinkage-reducing admixtures, proper curing methods, and well-graded aggregates. These methods enhance moisture retention and minimize excessive volume reduction.

Autogenous Shrinkage

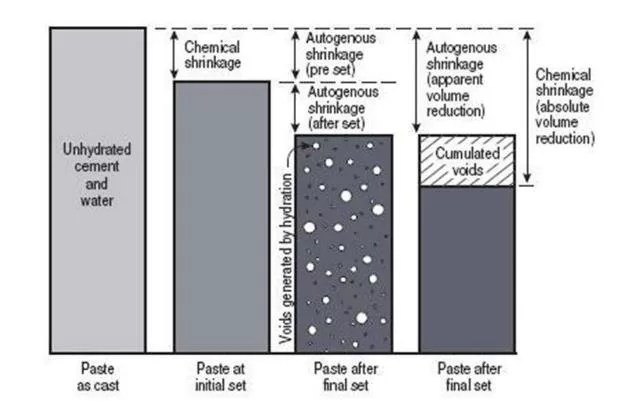

Autogenous shrinkage is common in high-strength, low water-cement ratio concretes where internal chemical reactions drive volume reduction. Unlike drying shrinkage, it occurs without external moisture loss and results from cement hydration reactions consuming water within the concrete. This type of shrinkage is more pronounced in self-consolidating and high-performance concretes, where fine particles create dense microstructures. To mitigate autogenous shrinkage, internal curing techniques are applied. Techniques such as using lightweight aggregates or superabsorbent polymers help retain water for extended hydration.

Thermal Shrinkage

Thermal shrinkage is caused by temperature variations during the early curing stages of concrete. Cement hydration generates excess heat, causing the concrete to expand. As it cools, the contraction leads to thermal stress and shrinkage cracks. Large structures, such as bridges and massive foundations, are particularly vulnerable to this effect. To control thermal shrinkage, low-heat cement manages heat dissipation. Temperature-controlled pouring also assists. Insulation methods minimize volume changes, preventing long-term structural issues.

Carbonation Shrinkage

Carbonation shrinkage occurs when carbon dioxide (CO₂) from the atmosphere reacts with calcium hydroxide in concrete to form calcium carbonate. This process slightly reduces concrete volume over time and primarily affects thin concrete sections exposed to high CO₂ levels. Although carbonation can increase surface strength, excessive shrinkage can cause microcracking. To limit carbonation shrinkage, proper curing, protective coatings, and low-permeability mixes help slow down CO₂ penetration and maintain durability.

Causes of Shrinkage in Concrete

Several factors contribute to concrete shrinkage, and understanding these is crucial for implementing effective preventive measures:

- Water Content: Excessive water in the concrete mix increases the potential for shrinkage. Maintaining appropriate water-cement ratios is critical to reducing this risk.

- Cement Composition: The type and amount of cement influence shrinkage. High cement content can lead to increased shrinkage due to greater heat of hydration.

- Environmental Conditions: High temperatures, low humidity, and wind can accelerate moisture evaporation, leading to increased shrinkage.

- Improper Curing: Inadequate curing can result in rapid moisture loss, causing shrinkage and cracking.

- Aggregate Properties: The size, type, and grading of aggregates affect the overall shrinkage

Effects of Concrete Shrinkage

Shrinkage can have several detrimental effects on structures:

- Cracking: As concrete shrinks, tensile stresses develop, leading to cracks, especially if the concrete is restrained.

- Reduced Durability: Cracks allow ingress of harmful substances like water and chlorides, which can lead to reinforcement corrosion and reduced lifespan of the structure.

- Structural Weakness: Significant shrinkage and cracking can compromise the load-bearing capacity of concrete elements.

How to Reduce Shrinkage in Concrete

To reduce shrinkage and its adverse effects, consider the following measures:

- Use Low Water-Cement Ratio: Reducing the amount of water in the mix decreases the potential for shrinkage. However, this must be balanced with workability requirements.

- Proper Curing Methods: Implement adequate curing practices. These practices maintain moisture in the concrete during the early stages. Use curing compounds or wet coverings.

- Use of Shrinkage-Reducing Admixtures: Incorporating admixtures can help reduce drying shrinkage and control crack widths.

- Optimized Mix Design: Selecting appropriate types and proportions of cement and aggregates can influence shrinkage characteristics.

- Environmental Control: Protecting concrete from extreme weather conditions, such as high temperatures and winds, can prevent rapid moisture loss.

Key Takeaways

- Definition: The volume reduction due to moisture loss and hydration reactions.

- Types: Includes plastic, drying, autogenous, thermal, and carbonation shrinkage.

- Influencing Factors: Water-cement ratio, environmental conditions, and material properties.

- Mitigation: Proper curing, shrinkage-reducing admixtures, and optimized mix designs are essential.

- Importance: Effective shrinkage management preserves structural integrity, enhances durability, and ensures sustainable construction practices.

FAQs

- What is concrete shrinkage?

- It is the reduction in volume of concrete over time due to moisture loss and chemical reactions during cement hydration.

- What causes this?

- Shrinkage is caused by factors like water loss, hydration reactions, temperature changes, and environmental conditions.

- What are the types of concrete shrinkage?

- The primary types include plastic, drying, autogenous, thermal, and carbonation shrinkage.

- How can this be minimized?

- By using a low water-cement ratio, proper curing techniques, shrinkage-reducing admixtures, and optimized mix designs.

- What effects does concrete structures?

- Shrinkage can cause cracking, reduce durability, and compromise the structural integrity and load-bearing capacity of concrete elements.

Conclusion

Concrete shrinkage involves a reduction in volume over time due to moisture loss. It also results from chemical reactions during hydration. This phenomenon poses a significant challenge for construction professionals. This blog has explored its various forms, including plastic, drying, autogenous, thermal, and carbonation shrinkage. The blog also examined the factors influencing shrinkage, such as water-cement ratio, environmental conditions, and material properties. Effective mitigation through proper curing, shrinkage-reducing admixtures, and optimized mix designs is crucial to prevent cracking and preserve structural integrity. By understanding these dynamics, engineers, contractors, and stakeholders can implement strategies that enhance durability and safety. Proactive management extends the lifespan of concrete structures. It also contributes to more resilient and sustainable construction practices. Ultimately, diligent control of shrinkage secures long-term performance and trust.