Types of rails form the backbone of rail transport and industrial applications, influencing safety, durability, and efficiency. Among the key types, double headed rails stand out historically as reversible rails designed for longevity. Meanwhile, bull headed rails/bull head rails feature a symmetrical profile often used in the UK for traditional railway systems. The most widely adopted is the flat footed rail, prized for its stability and economical installation over sleepers. In heavier industrial settings, industrial railway rails are engineered for robustness to support intense loads and specialized machinery. Additionally, crane rails offer exceptional strength and precision, facilitating smooth operation of overhead cranes in factories and ports. Understanding these variants is crucial, as each serves distinct purposes and optimizes performance under different conditions. Together, these types of rails demonstrate the versatility and technical evolution in rail infrastructure.

Let’s start from scratch. What are rails?

Table of contents

What are Rails?

Rails are an important component of railway track. They are the high carbon rolled steel sections, which are laid end- to- end, in two parallel lines over sleepers to provide continuous and levelled surface for the trains to move and for carrying axle loads of the rolling stock.

Besides providing a sturdy path for trains, rails effectively carry the axle loads of rolling stock, ensuring safe and stable operations. Different types of rails, such as bullhead rails, double headed rails, and flat bottom rails, cater to specific functions in the railway system. Selecting the appropriate rail type enhances track stability, durability, and overall performance. Familiarity with these rail sections is vital for optimizing the design and maintenance of railway infrastructure, supporting efficient and reliable rail transport.

Let’s deep into the types of rails.

Main Types of Rails

Rails are essential components that create a continuous, stable surface for trains to move safely and efficiently, directly impacting track durability and performance. They are made of high-carbon rolled steel sections laid end-to-end in parallel over sleepers, carrying the axle loads of the rolling stock. Various types of rails serve specific functions in railway and industrial operations. These include double headed rails, known for their reversible design; bull headed rails, commonly used in traditional British railways; and the widely adopted flat bottom rails (also called Vignole rails) favored for their stability. Additionally, industrial railway rails and crane rails provide specialized performance in heavy-duty and material handling settings.

Main Types of Rails are as follows

- Double Headed Rails

- Bull Headed Rails

- Flat Bottom Rails (Vignole Rails)

- Industrial Railway Rails

- Crane Rails

Double headed rails

Double headed rails indicate the early stage of development. It essentially consists of three parts, such as upper table, web and lower table. Both the upper and lower tables were identical and they were introduced with the hope of double doubling the life of rails.

When the upper table is worn out then the rails can be placed upside down reversed on the chair and so the lower table can be brought into use.

But this idea soon turned out to be wrong because due to continuous contract of lower table with the chair made the surface of lower table rough and hence the smooth running of the train was impossible.

Therefore, this type of rail is practically out of use. Nowadays, these rails vary in lengths from 20- 24.

The rail sections, whose foot and head are of same dimensions, are called double headed rails. In the beginning, these rails were widely used in the railway track.

The idea behind using these rails was that when the head had worn out due to rubbing action of wheels, the rails could be inverted and reused. But by experience, it was found that their foot could not be used as running surface because it also got corrugated under the impact of wheel loads.

Its time to meet the second type of rails which are bull headed rails.

Bull headed rails

The rail section whose head dimensions are more than that of their foot are called bull headed rails. In this type of rail the head is made little thicker and stronger than the lower part by adding more metal to it. These rails also require chairs for holding them in position.

Bull headed rails are especially used for making points and crossings. This type of rail also consists of three parts, such as the head, the web and the foot. These rails were made of steel.

The head is of larger size than foot and the foot is designed only to hold up properly the wooden keys with which rails are secured. Thus, the foot is designed only to furnish necessary strength and stiffness to rails.

Two cast iron chairs are required per each sleeper when these rails are adopted. Their weight ranges from 85lb to 95lb and their length is up to 60ft.

That’s it about bull headed rails. Let’s move on to the third member in the list of types of rails, which are flat footed rails.

Flat footed rails

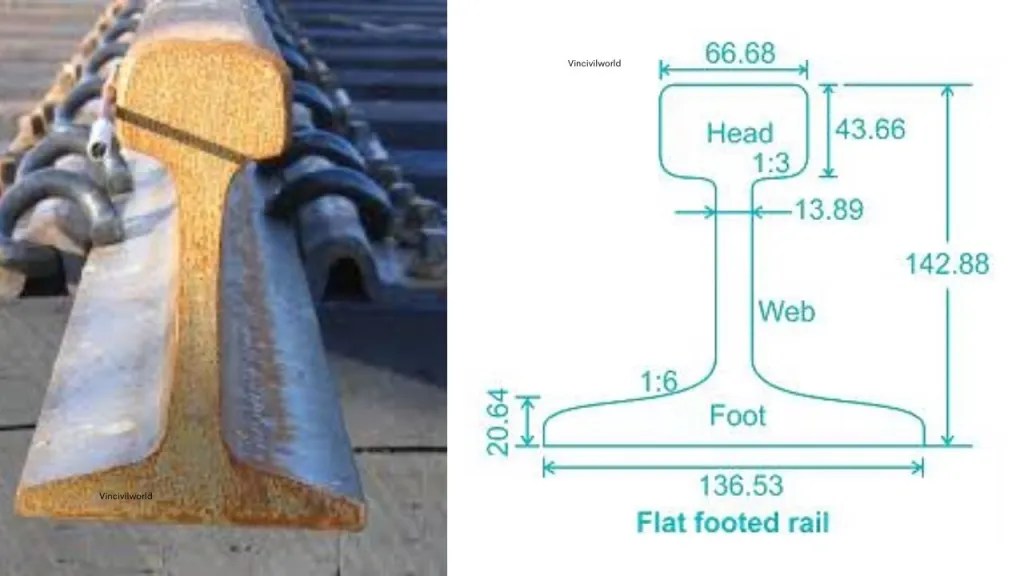

The rail sections having their foot rolled to flat are called flat footed rails. This type of rail was invented by Charles Vignola in 1836.

It was initially thought that the flat footed rails could be fixed directly to wooden sleepers and would eliminate chairs and keys required for the BH rails. But later on, it was observed that heavy train loads caused the foot of the rail to sink into the sleepers and making the spikes loose.

Flat footed rails consist of three parts, such as head web and foot. The foot is spread out to form a base. This form of rail has become so much popular that about 90% of railway tracks in the world are laid with this form of rails.

Flat footed rails have the following advantages.

Advantages of flat footed rails

- They do not need any chair and can be directly spiked or keyed to the sleepers. Thus they are economical.

- They are much stiffer both vertically and laterally. The lateral stiffness is important for curves.

- They are less liable to develop kinks and maintain a more regular top surface than bull headed rails.

- They are cheaper than bull headed rails

- The loads from wheels of trains are distributed over large number of sleepers and hence larger area which results in greater track stability, longer life of rails and sleepers, reduced maintenance, costs, rail failure and few interruptions to traffic

Industrial Railway profiles

Industrial railway rails are specially designed rails used in industrial environments such as factories, mines, and ports. These rails are heavier and more robust than conventional railway rails to withstand high axle loads, frequent stopping and starting, and harsh conditions. Typically, they conform to standards like the AREMA Class 1 and can weigh between 112 to 141 pounds per yard. Industrial rails provide durability, strength, and resistance to wear, ensuring reliability for transporting heavy goods and equipment within industrial premises.

Crane Rails

Crane rails are specialized rails designed to support the movement of overhead cranes and gantry cranes in industrial facilities. They have a wider head and base to provide stability and distribute heavy crane loads evenly. Crane rails are typically more rigid and wear-resistant than standard rails, often stocked in weights like 60 kg/m or higher. They ensure smooth crane operation, safety, and longevity under continuous heavy loading and lateral stresses encountered in crane tracks.

The Most Used Rail Profiles Worldwide Presently

In contemporary railway engineering, the flat footed rail profile, also known as the Vignole rail, is the most widely used rail profile globally. This profile is characterized by a flat, wide foot that can be spiked directly to sleepers, eliminating the need for additional support such as chairs. Flat footed rails are favored for their structural efficiency, durability, and ease of installation, making them ideal for standard and heavy-duty railway tracks.

Common modern flat footed rail profiles include the internationally standardized UIC60 (60 kg/m), prevalent on mainline railways worldwide, and the 115RE profile (approximately 56.9 kg/m), widely used in North America. Regional variations such as DIN rails in Europe and other heavy or light profiles also follow the flat bottom design. These flat footed/Vignole rails offer superior load distribution, enhanced stability, and cost advantages over traditional bull headed rails, leading to their dominant use in global rail infrastructure.

Key Takeaways

Understanding the various types of rail is essential for optimizing railway infrastructure. Types of rail sections include double-headed rails, bull-headed rails, and flat-footed rails. Double-headed rails have symmetrical upper and lower tables. They aimed to extend rail life. However, they are now rarely used due to maintenance issues. Bull-headed rails feature a thicker head for strength and are commonly used in points and crossings. Flat-footed rails, introduced by Charles Vignole, are widely adopted in modern railways due to their ease of installation and cost-efficiency. Each of these types of rail sections serves specific needs, influencing track stability and performance.

Conclusion

In conclusion, the selection of rail types profoundly affects railway system efficiency. Types of rail sections, such as double-headed rails, bull-headed rails, and flat-footed rails, each have distinct characteristics and applications. Double-headed rails are largely obsolete, while bull-headed rails remain useful for specific rail components. Flat-footed rails, with their practical advantages, dominate modern rail systems. A comprehensive understanding of the types of rail and their properties is crucial. This is essential for effective rail system design and maintenance. It ensures optimal performance and longevity.

We have reached the end of the journey diving through various types of rails.

MUST READ: Applications of Intelligent transportation system- everything you want to know

Was the article helpful? Let me know your thoughts in the comments.

Happy learning!

please allow allow a back link for me for this post