Vitrified tiles are ceramic tiles with less porosity. Various types of vitrified tiles are available for catering to different functional requirements. Vitrified tiles are considered as a superior quality tile compared with ceramic tiles because of their excellent water-resistant and frost-resistant qualities, aesthetic looks, and durability. They are well suited for external and internal flooring and cladding applications and are used as an alternative to marble and granite.

What are vitrified tiles?

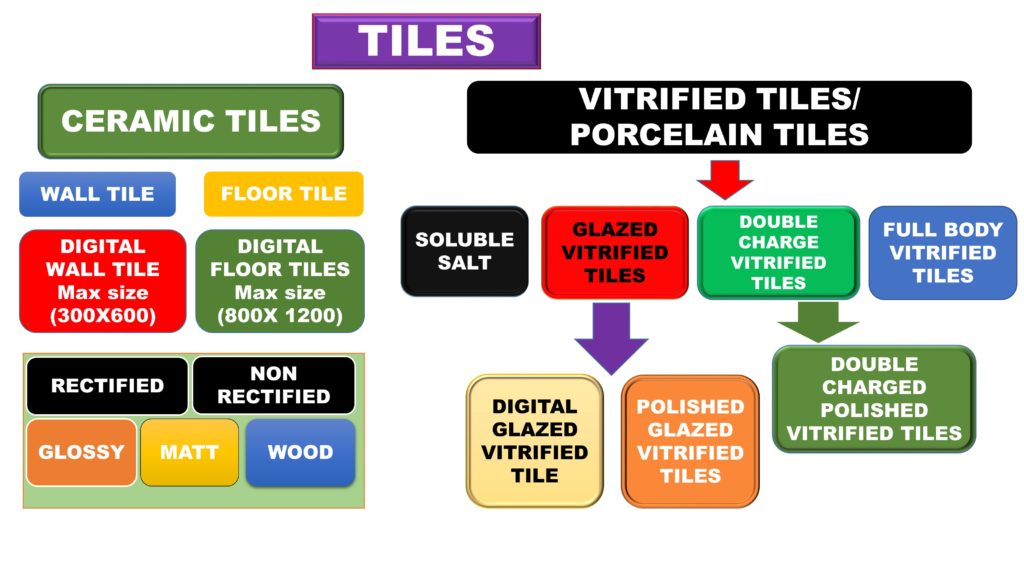

Tiles are classified into vitrified tiles and ceramic tiles. Vitrified tiles are manufactured by mixing clay with silica, quartz, and feldspar, pressed and heated in kilns whereas ceramic tiles are made from natural clay, moulded, and heated in kilns. The high pressure applied during the hydraulic pressing followed by the Vitrification process is responsible for imparting the superior qualities in vitrified tiles.

Vitrified tiles can withstand abrasion and maintain the surface quality and charm for several years. Vitrified tiles are available in a variety of patterns, designs, textures, and types and can match any colour schemes. Hence they are preferred for numerous applications in residential, commercial, and industrial works.

Also read : Ceramic tiles – Types and uses

Vitrified tiles manufacturing process

Vitrified tile is made by hydraulic pressing a mixture of clay, quartz, feldspar, and silica. The hydraulic pressed tiles are heated in kilns at a temperature of around 1000-1400 degrees centigrade. The ingredients like Quartz, silica, and feldspar melts and transforms into a glass-like hard layer. This process of manufacturing is called the vitrification process which means making like glass. At high temperatures, the molten silica fills the gaps and air bubbles thereby making the surface extremely strong and non-porous. The manufacturing process is the one that makes vitrified tiles a much superior option to ceramic tiles. The vitrification process makes vitrified tiles dense, non-porous, abrasion-resistant, and durable than ceramic tiles.

Properties of Vitrified tiles

- Vitrified tiles are superior flooring materials and are available in a wide range of textures and shades and posses a lot of unique qualities.

- They are available in a wide range of colours, shades, and textures and can match any interior colour scheme of the structure.

- Vitrified tiles are durable, dense, non-porous, and strong material. They have a Flexural strength of around 35 N/ mm2 and breaking strength of around 700 N.

- Water absorption of vitrified tiles is less than 0.5% due to its non-porous quality. Hence they are preferred for external and wet areas.

- Ceramic tiles have to be glazed whereas vitrified tiles do not need any glazing. The vitrification process transforms the surface into a glass-like layer.

- Vitrified tiles look aesthetically elegant with a smooth texture and glossy looks. Vitrified tiles do not fade easily and can maintain the charm and looks for an extended period.

- Due to the vitrification process, they possess high abrasion-resistant qualities and are preferred for high traffic areas.

- Vitrified tiles are very easy to fix and generates less wastage due to its high breaking strength. They are very easy to clean and maintain due to its high stain-resistant properties.

- Vitrified tiles are anti-skid and possess anti-bacterial qualities.

Also read : Difference between Vitrified tile and ceramic tiles

Types of Vitrified tiles

Vitrified tiles are available in a wide range of variations to cater to any functional requirements and costs. They can cater to high traffic areas like airports, metro stations, railway stations, industrial uses, etc to small residential uses. The category and types of vitrified tiles are tailor-made for adapting to any application.

Vitrified tiles are broadly classified into

- Soluble salt vitrified tiles

- Glazed vitrified tiles,

- Double charge vitrified tiles

- Full body vitrified tiles

The classification is based on the method of manufacturing, method of vitrification, material qualities, density, type of traffic, color choices and functions.

Also read : Ceramic, vitrified tiles: Sizes, Finish,price comparison & applications

Soluble salt vitrified tiles

The liquid screen printing technique is used for soluble salt vitrified tiles. The single colour of soluble salts provides the colour layer on the surface of the tiles. These tiles are heated in a kiln and polished for use. The main problem with soluble tiles is that the colour fades gradually and losses the original sheen and looks very dull. Colour choice is very limited for Soluble vitrified tiles and is replaced by double charge vitrified tiles having much more flexibility in terms of colour and design choices. Soluble salt vitrified tiles are normally ivory colour based tiles.

Glazed Vitrified tiles (GVT)

Glazed vitrified tiles are vitrified tiles with glazing. These tiles are very much similar to ceramic tiles. Due to the vitrification process involved in the production method, they possess high strength, durability, and excellent water repellent qualities.

Type of GVT tiles are Digital Glazed Vitrified tiles (DGVT) and Polished Glazed Vitrified tiles (PGVT tiles)

Also Read : Difference between Digital Glazed Vitrified Tiles and Double charge Vitrified tiles.

Digital Glazed Vitrified tiles (DGVT)

Glazed vitrified tiles uses digital inkjet printing technology and hence it is called Digitally glazed vitrified tiles. Due to the involvement of digital printing technology the design choices are unlimited and can print rich textures and designs over the tiles. Marble patters, wood patters and anything can be print on the tiles using digital inkjet printing technology. This is only possible in the case of Glazed vitrified tiles.

The digital designs are printed on a 1mm – 2 mm thick glazing layer which provides the required protection and long-lasting charm to the tiles. These tiles are comparatively cheap and can be used for medium traffic residential and commercial applications. This is the most commonly used tiles now a days.

These tiles may scratch and fade in long run due to the lesser top layer bearing the textures and prints.

Polished glazed Vitrified tiles (PGVT)

Digitally glazed vitrified tiles are further polished for extra glossiness. Then the tiles are known as Polished Glazed Vitrified tiles. These tiles are mostly used for residential and commercial applications involving moderate traffic.

Double charged Vitrified tiles (DCVT)

Double charged vitrified tiles are also called double-loaded tiles. They are made from a mixture of clay, quartz, feldspar, and silica. They do not have a glazed layer and hence digital printing is not possible in these tiles. For Double charged vitrified tiles the designs are formed with a double layer of pigment having a thickness of 3-4 mm thick. That means the upper layer of the design mix is 3-4 mm thick and contributes almost 30% of the total tile thickness. These layers are pressed and fused to become a part of the tile body and not a layer as in Glazed Vitrified tiles. The tile surface is further nano-polished for making it non porous, extremely durable and abrasion-resistant with superior qualities.

Double charged vitrified floor tiles are by far the most preferred choice in flooring for Residential, commercial and industrial projects because of the simple reason that they can withstand heavy traffic and need extremely low maintenance and last longer and gives a fresh look when compared to Ceramic and Glazed Vitrified tiles. They are scratch resistant and abrasion resistant and can resist all climatic conditions.

Full Body Vitrified Tiles

This type of vitrified tiles has colour all the way throughout the body (thickness) of the tile. Because of this scratches are less noticeable in this type of tiles. Full body vitrified tiles are formed with the paint mixture pre-added while making the body. The design is in the total thickness of the tile and got a uniform shade through out the tile body.

Design will never fade because it is spread over the entire body of tiles. Full body tiles are ideal flooring choice for heavy traffic areas, industrial structures, airports etc. These tiles are less preferred in residential construction due to their higher costs.

Conclusion

All types of vitrified tiles are good when chosen based on the functional requirements.

Comments are closed.