WPC boards or Wood Plastic Composite (WPC) is a hybrid product manufactured by mixing sawdust and plastic materials. WPC boards are used in a wide range of structural and non-structural applications due to their superior qualities and strength when compared with any other materials used for the same purpose. They are one of the best alternatives for natural wood and plywood as they come with add-on features like water-resistant, no decay, design flexibility, ease of working, colour choice, etc. They are extensively used for facades, swimming pool decks, doors, windows, interiors, furniture, etc. Let us go through its unique properties and applications.

Materials used for interior works

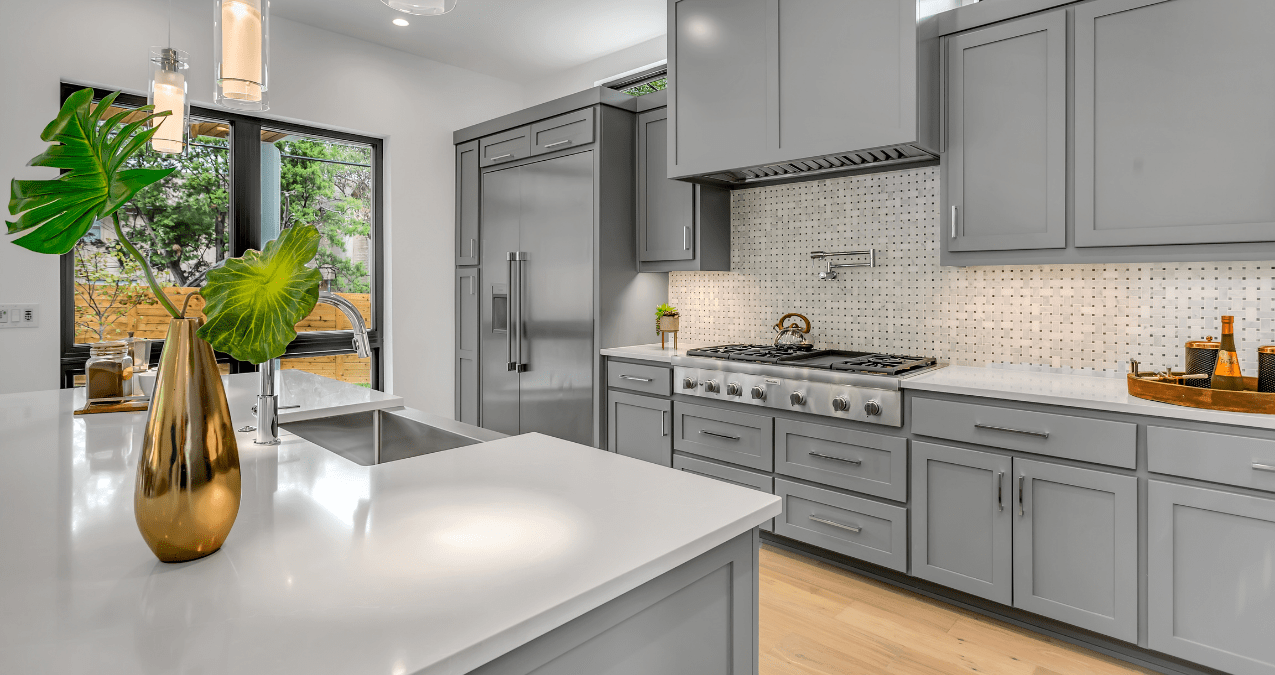

For making a room usable and the interiors to be set up in the right direction. Interior materials for modular kitchen, wardrobes, cabinets, etc has to be made with durable materials that have to look elegant and long-lasting. Here we are listing a few commonly used materials.

- Particle board

- MDF

- HDF

- PVC or Multiwood

- Plywood

- WPC or Wood plastic composite

All these materials can be used as an alternative for wood. But why WPC boards are best and preferred choice. Let us go through the facts..

WPC boards – Ingredients

WPC is made from grounded sawdust thoroughly mixed and heated with thermoplastic resins mixed with additives for imparting superior qualities. Sawdust from fibre fillers like pulp, peanut hulls, byproducts of the textile industry, bamboo, etc. are mixed with virgin or waste/recycled plastic derived from polyethylene, polyvinyl chloride, polypropylene, etc. Nowadays polyethylene-based plastics are commonly used. The proportion of sawdust is around 15%, virgin/recycled plastic constitutes 75%, and the remaining will be different additives. WPC board is a hybrid product that got the qualities of wood and easiness and water-resistant properties of plastic. These ingredients are mixed to a thick consistency and are moulded or extruded to form WPC boards.

WPC boards – Manufacturing process

The ingredients are mixed to achieve a relatively thick consistency and are extruded or moulded. Additives, such as pigments, binding agents, and lubricants are added for extra strength and other superior properties. WPC products got high cellulose content and hence can be moulded to any shape and size. They can be treated as wood which can withstand moisture and rot-resistant.

WPC boards – Properties

WPC boards are available in 4 ft x 8 ft (1220 x 2440 mm) sizes. and available in thickness of 5 mm, 6 mm, 8mm/7.5 mm, 10 mm, 12 mm, 15 mm, 17 mm, 18 mm, 20 mm, 25 mm. They are available in low density, medium density, and High density. With these variations in densities, we can choose them based on areas of usage. The density of around 600 kg /cum is idle for good screw holding capacity.

Advantages of WPC boards

WPC boards got superior qualities which stand out from other conventional materials and wood substitutes.

Green and environmental friendly product

Biodegradable materials and 100 % recyclable materials like wood waste, industrial waste, agricultural waste, plastic waste, etc are used in the production of WPC boards. No trees are cut in the making process of WPC boards.

The extrusion process consumes almost 100 % raw material without generating wastage. The process does not emit any hazardous chemicals like formaldehyde or any VOCs. WPC boards can be an integral part of green buildings.

WPC boards are reusable products and almost all manufacturers sell with buyback guarantee if returned as plain material.

Water resistant and Heat resistant properties

WPC boards are moisture and heat resistant than any other conventional building materials. They are preferred over marine plywood, wood, and other similar products for modular kitchen cabinets, partition, wardrobes, etc.

WPC board got excellent water-resistant properties, they do not wear and tear, and will not fade on exposure to the external atmosphere. Because of these properties, WPC boards are used for external applications like facades, decking for swimming pools, landscape items, garden furniture, garden fencing, flower pots, etc. due to its low maintenance.

Durability

WPC boards are highly durable and are not affected by any of the climatic changes like rain, snow, humidity, and chemicals, etc. Hence they are used for external applications.

Because of its high density, all types of screws and nails can be easily fixed with the help of a conventional tool. WPC boards have better screw and nail holding capacity than plywood and can even screw and unscrew multiple times in a single spot without failure.

They do not need any coatings and maintenance like that of wood and do not fade on exposure to sunlight.

Colour and coatings

WPC boards are available in a variety of colours and do not require any protective coatings. They can also be painted using textured and PU paints but care should be taken to apply plastic primers. WPC boards can also be laminated and veneered after applying required surface preparations.

Ease of fixing

WPC can be moulded into different shapes and sizes. They can be cut, grooved and moulded easily with conventional tools and gives an elegant and classy look.

Termite resistant

WPC do not corrode and are highly resistance to rot, decay and marine borer attack. They do not absorb any moisture like plywood and conventional wood.

Fire resistant

WPC material is highly fire resistant and fire retardant material. Plywood burns with flame whereas WPC do not burns with flame. That is why it is preferred for kitchen interiors.

Disadvantages of WPC boards

The short coming of wood and plastic is evident in WPC boards

The initial cost is comparatively high compared to other alternative materials used for the same purpose.

The wooden finishes gives and artificial looks when used in interiors, doors and windows.

They are not resistant to high temperatures. Hot utensils when placed over WPC board gives a melting impression if the temperature is more than 90-100 degree.

Laser cutters may burn the product.

WPC requires minor maintenance. If used for horizontal surface scratches will be formed.

Applications of WPC boards

Due to its superior qualities like water resistant, termite resistant, and other properties they are used for a lot of applications both internal and external.

External applications

They are used for facades, decking of swimming pools, garden furniture, landscape components, park benches , planter boxes, outdoor panelling,doors , windows etc

WPC boards can be used in signboards, display boards, direct digital printing, exhibitions stands & graphics.

Interior applications

They are used for interior ceiling, kitchen cabinets, bathroom vanities, interior partitions, modular furnishing, household furniture, doors, windows , railing, wall panellings etc.

Conclusion

WPC is an innovative material which has proven its ability as one of the most sustainable and eco friendly option with add on like moisture resistance and fire resistant qualities. They can act as a perfect alternative if used in a systematic way.

Comments are closed.