Air pollution control measures play a critical role in reducing harmful emissions released from industrial processes and protecting air quality. Rapid industrialization has increased the demand for effective industrial air pollution control devices that can capture, neutralize, or eliminate pollutants before they enter the atmosphere. Industries today rely on advanced air pollution control devices to manage particulate matter, toxic gases, and volatile organic compounds. Implementing well-designed industrial air pollution control measures helps industries comply with environmental regulations while safeguarding worker health and nearby communities. Various types of air pollution control equipment, such as scrubbers, bag filters, and electrostatic precipitators, work together in industrial facilities.

They form integrated air pollution control systems that effectively capture and remove pollutants from industrial emissions. These systems act as reliable industrial emission control devices, ensuring cleaner exhaust and sustainable operations. Understanding the selection, working principles, and applications of these devices is essential for achieving efficient pollution abatement and long-term environmental protection.

It’s the need of the hour to take measures for air pollution control and prevention since millions of Indians are constantly exposed to polluted air. For instance, they breathe up to 25 micrograms/cubic metre of the lethal, microscopic pollutant PM 2.5 on a 24-hour average. This is well above the World Health Organization’s (WHO) limit of 10 micrograms/cubic metre.

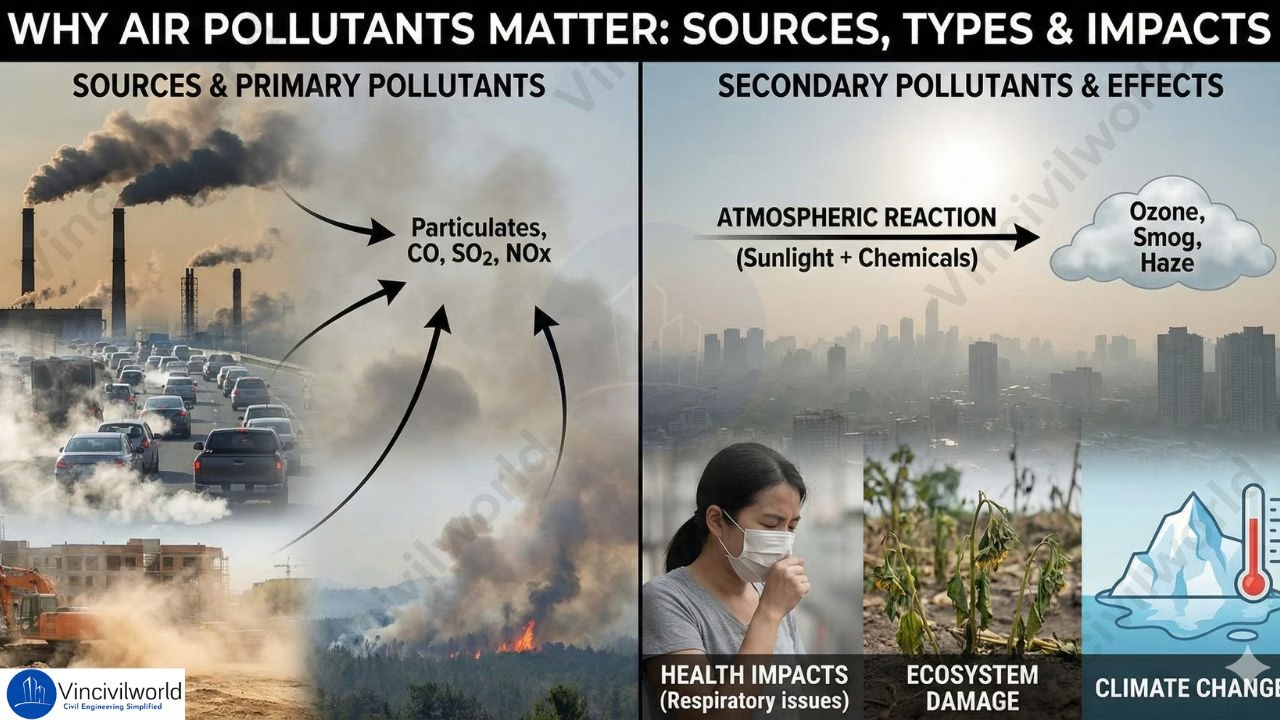

To begin with, let’s first look at the causes of air pollution.

Table of contents

Causes of Industrial Air Pollution

Causes of industrial air pollution stem mainly from fuel combustion, manufacturing processes, chemical reactions, and improper waste handling. Power plants, refineries, cement plants, and metal industries release particulate matter, sulfur oxides, nitrogen oxides, and toxic gases. Outdated equipment, poor emission controls, and rising industrial demand further intensify air pollution levels.

Industrialisation and urbanisation have technologically upgraded our lives. But, they had some negative by-products like degradation of the environment, air pollution etc. The air quality index in most of the metropolitan cities is alarmingly high. Let’s have a quick glimpse at some of the major causes of air pollution:

- Emissions from Industries and Power Plants

- Construction and Demolition

- Mining

- Vehicular Emissions

- Burning of waste and stubble

If you wish to dig deeper into the causes of air pollution, please check our blog Air Pollution Causes – A Comprehensive Guide

We can control air pollution by preventing the release of toxic gases. This is achieved by removing them from the flue gas stream or converting them into harmless compounds. Similarly, if we can collect the dust and dispose of it properly, we can avoid particulate pollution.

Also read: Air Pollution Effects and Causes – A complete overview

Industrial Air Pollution Control Measures and Devices

Industrial air pollution control equipment includes devices and facilities used in industries. These systems control and prevent the emission of particulate matter and toxic gases. Fans or blowers direct industrial emissions and pollutants into air pollution control equipment and systems. Subsequently, they eliminate or reduce air pollutants using one or more of the following procedures:

- Combustion i.e., destroying the pollutant.

- Conversion i.e., chemical conversion of the pollutant to a less harmful compound.

- Collection i.e., removal of the pollutant from stack gas before releasing into the atmosphere.

We have understood the basic working mechanisms of pollution control devices. Now, let’s take a closer look at the different types of industrial air pollution control systems and equipment.

Scrubbers

Scrubbers are among the most widely used types of air pollution control equipment in industrial production and manufacturing facilities. They work on the principle of scrubbing, where polluted gas streams come into contact with a liquid or solid medium to remove particulate matter and harmful gases. Scrubbers effectively control sulfur dioxide, acidic gases, and fine particles before emissions are released into the atmosphere. Based on their operating method, scrubbers are classified into wet scrubbers and dry scrubbers. Each one is selected according to pollutant type, gas temperature, and efficiency requirements.

- Wet Scrubbers

- Dry Scrubbers

Dry Scrubbers

Dry scrubbers treat industrial exhaust gases using effective air pollution control technology.

They inject dry neutralising chemicals such as sodium bicarbonate or hydrated lime into the gas stream.

These chemicals react with acidic gases and convert them into harmless compounds. The reaction leaves spent products within the gas flow. High-efficiency filters or fabric baghouses remove these particles from the gas. Industries widely use dry scrubber systems for acid gas neutralisation. Oil refineries, wastewater treatment plants, and metallurgical industries commonly use them. Low water use and compact design make dry scrubbers efficient and environmentally friendly.

Wet Scrubbers

Also known as wet adsorption scrubbers or wet collectors, wet scrubbers actively remove water-soluble gases and particulate matter from industrial exhaust streams as widely used air pollution control systems. In the wet scrubbing process, the polluted gas stream either passes through a liquid solution, or the system injects the liquid—typically water or a chemical solution—directly into the gas stream. When the liquid comes into contact with the gas, it absorbs and captures the pollutants through physical and chemical interaction. This process effectively removes contaminants and releases cleaned gas into the atmosphere. Common types of wet scrubbers include venturi scrubbers, packed bed scrubbers, and bubbling scrubbers. Flue gas desulphurisation (FGD) systems extensively use wet scrubbing with alkaline sorbents such as limestone or lime to control sulfur dioxide emissions from industrial plants.

Air Filters

- Air filters are widely used air pollution control systems in many industries.

- They operate using specialised filtration media such as fabric, ceramic, and synthetic fibres.

- Air filters capture and remove dry particulate matter and airborne contaminants.

- These include dust, pollen, microorganisms, fumes, and chemical particles.

- Polluted air passes through the filter medium during operation.

- Air filters remove pollutants from exhaust air effectively.

- They improve indoor and process air quality in buildings.

- Common industrial air filters include HEPA filters and baghouses.

- Cartridge dust collectors and pleated filters are also widely used.

Bag Filters

Bag filters, also known as baghouses or fabric filters, function as highly efficient air pollution control devices and industries widely use them for emission control. A bag filter system uses cylindrical fabric bags to trap and remove dust and other airborne pollutants from contaminated air streams. As polluted air passes through the baghouse, particulates accumulate on the surface of the filter bags. This dust cake formation actually improves filtration efficiency by reducing pore size, allowing even finer particles to be captured. Fabric filters typically achieve collection efficiencies exceeding 99.9%, making them ideal for strict emission standards.

Bag filters are commonly used as Industrial emission control devices for power plants, metal processing units, cement plants, and foundries. Due to continuous dust buildup and rising pressure differential, periodic cleaning is essential. Cleaning methods include mechanical shaking and reverse air or pressure pulses that deform the bags to dislodge collected particles. The removed particulates fall into a hopper for safe collection and disposal.

HEPA Filters

HEPA (High-Efficiency Particulate Air) filters function as advanced air filtration devices and remove extremely fine particles from air streams with very high efficiency. A true HEPA filter can capture at least 99.97% of particles as small as 0.3 microns, including dust, smoke, bacteria, allergens, and fine aerosols as per US Department of Energy (DOE) . These filters use dense mats of randomly arranged fibres that trap particles through interception, impaction, and diffusion mechanisms. Industries widely use HEPA filters in clean rooms, pharmaceutical plants, laboratories, hospitals, food processing units, and precision manufacturing facilities. In industrial air pollution control systems, engineers often install HEPA filters as final-stage filters to ensure ultra-clean exhaust air and protect sensitive environments.

Cyclones – Industrial air pollution control measures

Cyclones, also known as cyclone dust collectors, serve as widely used industrial air pollution control measures and remove particulate matter from exhaust gas streams using centrifugal force. When polluted gas enters the cyclone chamber, it follows a high-speed spiral motion inside the cylindrical or conical body. The centrifugal force generated by this rotating flow is much greater than gravitational force, causing heavier and coarser particles to move outward toward the chamber walls. These particles lose momentum, slide downward, and collect in a hopper at the bottom of the cyclone. Meanwhile, the cleaned gas stream moves upward through the central outlet and exits the system. Industries commonly use cyclone separators as pre-cleaners before bag filters or scrubbers because of their simple design, low maintenance, and ability to handle high-temperature and high-dust-load applications.

The separation factor of a cyclone is defined as the ratio of centrifugal force to gravitational force. The higher the separation factor, the better is the cyclone performance.

Electrostatic Precipitators – Industrial air pollution control measures

Electrostatic Precipitators (ESPs) function as highly efficient industrial air pollution control measures and collect and remove particulate matter such as dust, smoke, and fine aerosols from industrial exhaust gases. Similar to air filters and cyclones, ESPs function as industrial emission control devices, but they rely on electrostatic forces rather than mechanical filtration. In an ESP, transformers create a large static electrical potential difference between the discharge (emitter) electrodes and the collecting plates. At very high direct current voltages, typically around 50 kV, a corona discharge forms near the negative electrode.

This corona discharge generates a strong electric field between the negatively charged emitter and the positively charged or grounded collecting plates. As the particle-laden gas stream flows through the ESP, the electric field ionises the particulate matter. The resulting electrostatic force drives these charged particles toward the collecting plates, where they adhere to the surface. Rapping or vibration periodically removes the accumulated particulate matter from the plates and discharges it into the collection hopper below.

Wet electrostatic precipitators use water sprays to continuously rinse the collecting surfaces, making them effective for sticky or fine particles. ESPs can achieve collection efficiencies of up to 99%, especially due to the presence of multiple collecting plates. The Deutsch equation is commonly used to estimate the collection efficiency of an electrostatic precipitator under ideal conditions.

Mist Collectors

Mist collectors, also known as mist eliminators or moisture eliminator filters, function as specialised air pollution control devices and remove liquid droplets, vapours, and aerosols from industrial gas streams. These systems effectively capture contaminants such as oil mist, acid mist, smoke, and moisture generated during industrial processes. Mist collectors typically use fine mesh, fibre bed, or vane-type filter media to separate liquid droplets from the gas stream and channel them into a dedicated collection chamber. They are widely used in food processing units, chemical plants, desalination facilities, paper and pulp mills, and metalworking industries. For submicron liquid particles, mist collectors deliver exceptional performance, with advanced systems achieving up to 99.9% efficiency for particles as small as 0.3 μm, ensuring cleaner exhaust air and compliance with emission standards.

Shall we wrap up?

Key Takeaways

- Industrial air pollution control measures are essential for reducing emissions and protecting air quality.

- Rapid industrialisation has increased the need for effective air pollution control devices such as scrubbers, bag filters, and electrostatic precipitators.

- These devices are critical for managing particulate matter and harmful gases, ensuring compliance with environmental regulations.

- Causes of industrial air pollution include emissions from factories and power plants, construction, and vehicular emissions.

- To achieve cleaner air, implementing advanced air pollution control measures and using green technologies is crucial.

Conclusion – Industrial Air pollution control Devices

Industrial air pollution control equipment is essential for reducing harmful emissions and improving air quality. Systems such as scrubbers, cyclones, bag filters, electrostatic precipitators, HEPA filters, and mist collectors effectively control particulate matter and toxic gases from industrial exhaust. Choosing the right air pollution control devices based on emission characteristics and process requirements helps industries meet environmental regulations. Proper implementation of industrial air pollution control measures supports cleaner production, protects public health, and promotes sustainable industrial and environmental development.

In this blog, we saw some air pollution control measures and For the effective control of air pollution, the National Green Tribunal and the pollution control boards should strictly monitor and ensure the usage of these devices in the industries. We are still in need of green technologies like solar cells for power generation instead of coal-fired power stations, clean coal technologies, electric vehicles etc. Together, it is possible to reduce and control air pollution for a green future.