Flow table test of concrete is a common method to measure the workability of fresh concrete. It is especially useful for mixes that are too fluid for the slump test. This test helps check how easily concrete flows, which is important for quality construction. In the flow table test for concrete, a flow table apparatus spreads the concrete, and the flow diameter is measured. Compared to the slump test, the flow table test procedure for concrete works better with high workability and self-compacting mixes. Knowing the difference between flow table test vs slump test helps engineers choose the right method. By following standards like ASTM C124 or EN 12350-5 and IS1199, the flow table test apparatus for concrete gives reliable results. This makes it a key test for concrete workability in construction projects.

In this article, we will explain the purpose and importance of the flow table test for concrete, especially in measuring workability and consistency for high-fluidity mixes like Self compacting Concrete (SCC) . You will learn about the standard codes (including IS 1199:1959, IS 5512:1983, ASTM C124, and EN 12350-5), the apparatus required, and the step-by-step procedure for conducting the test. We will also discuss the advantages, limitations, and practical applications of the flow table test in civil engineering projects. By the end, you’ll understand when and why to use the flow table test for concrete, and how it helps ensure quality and performance in construction

Table of contents

Significance of Quality tests on concrete

Quality tests on concrete are essential for ensuring strength, durability, and performance in construction. These tests help engineers assess the workability of fresh concrete and the quality of hardened concrete. Common quality tests on concrete include checks during the production stage (on fresh concrete before placing), tests on hardened concrete specimens, and evaluations performed directly on finished structures. Including tests like the flow table test for concrete ensures reliable results and consistent quality throughout a project.

Quality tests performed on concrete are classified into

- Production stage quality tests ( On fresh concrete before placing)

- Hardened stage quality tests ( hardened concrete specimens)

- Non Destructive tests On structures ( tests done on the structures )

Also read : Bitumen tests – 9 lab tests for bitumen

Production stage quality tests on fresh concrete

Production stage quality tests on fresh concrete are crucial for ensuring the right workability and consistency before placement. These tests help engineers select the best mix for construction and maintain quality control. Key tests include the slump test, compaction factor test, Vee-Bee test, Kelly ball test, and the flow table test for concrete.

This article focuses on the flow test of concrete, explaining its procedure, importance, and how it compares with other workability tests like the slump test and compaction factor test.

Flow table test for Concrete

The flow table test for concrete is a simple laboratory method used to measure the workability and flowability of fresh concrete, especially for highly workable mixes where the slump test is not suitable. In this test, the workability of concrete is determined by observing how much the concrete spreads on a flow table after being jolted. This spreading, or flow, directly indicates the concrete’s consistency and fluidity, which are essential for quality control in construction.

The flow table test is particularly useful for high or very high workability concrete that would otherwise collapse in a standard slump test. It provides insights into the consistency and cohesiveness of the mix, helping engineers ensure that the concrete can be easily placed and compacted without segregation. This method is best suited for concrete with a nominal maximum aggregate size less than 38 mm.

Standards for flow table test of concrete

- IS 1199 (Part 6): 2018

- ASTM C 124 – 39 (Re-approved 1966)

- BS 1881 :105: 1984

Flow table test of concrete as per IS 1199 (Part 6): 2018

The flow table test as per IS 1199 (Part 6): 2018 is a standardized method to determine the workability and flowability of fresh concrete, especially for self-compacting concrete. It measures the spread of concrete after the flow table is repeatedly dropped, indicating the concrete’s consistency and ability to flow without segregation

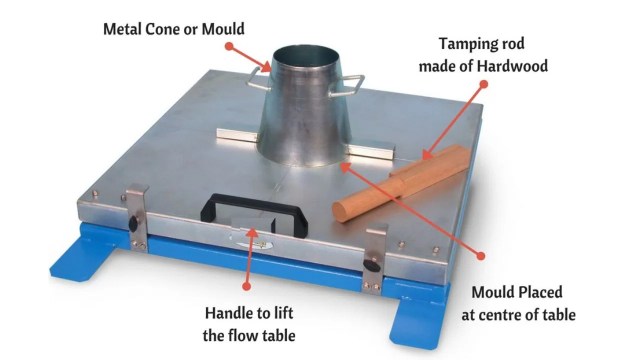

Flow table test apparatus Used as per IS 1199

The following apparatus are used to perform the flow table test:

- Flow table

- Mould

- Scale

- Hand scoop

- Trowel

- Tamping rod

Flow Table: A metal table with a flat surface and a hinged base, dropped to measure the concrete’s spread, indicating its workability.

Scale: A measuring device used to accurately measure the diameter of the concrete spread on the flow table, ensuring precise results.

Hand Scoop: A tool used to transfer concrete into the mold, ensuring an even and consistent sample for testing.

Trowel: A flat, metal tool used for smoothing and leveling the concrete surface within the mold, ensuring uniformity.

Tamping Rod: A rod used to compact the concrete inside the mold, removing air pockets and ensuring consistency in the sample.

Mould: A metal conical mold used to shape the concrete sample before spreading, essential for standardized measurements in the flow test. The shape of the mould for the flow table test is a cone frustum. The base diameter of the mould is 25 cm and the upper diameter is 17 cm. It has a height of 12 cm. A handle is also present on the sides of the mould.

Flow table Test procedure

- Before starting the test, wet and clean the tabletop and the mould from gritty materials.

- Keep the mould firmly at the centre of the table.

- Now fill two-layer, each layer should be one half of the volume of the mould.

- Tamp each layer 25 times using a tamping rod uniformly.

- After tamping the top layer, struck off the excess concrete using the trowel.

- Also, clean the area of the table outside the mould.

- Then remove the mould immediately by steady upward pull.

- Raise the table and drop at 12.5 mm, 15 times in 15 seconds.

- Measure the diameter of the concrete spread about its 6 direction and compute its mean value.

Calculation for Flow table test

The percentage increase in the average diameter of the spreading concrete over the base diameter of the mould is called the flow of concrete.

Flow% = (Spread diameter in cm – 25) / 25 * 100

The value of flow test varies from 0 to 150%.

According to ‘A.M. Neville, honorary member of the American Concrete Institute’, this flow table test is appropriate for concrete mixes having a flow of 340 to 600 mm.

Key Takeaways

The flow table test is an essential method for assessing the workability and flowability of fresh concrete, especially for high-fluidity and self-compacting mixes where the slump test is inadequate. By following standards like IS 1199 (Part 6): 2018, this test provides reliable, repeatable results crucial for quality control in construction projects. The apparatus is simple, and the procedure is straightforward, making it widely accessible in laboratories. The test helps engineers ensure the mix can be easily placed and compacted without segregation, directly impacting the durability and performance of the finished structure. Understanding the differences between the flow table and slump tests helps select the appropriate method for each concrete type, ensuring optimal construction quality.

Conclusion

In conclusion, the flow table test, as outlined in IS 1199 (Part 6): 2018, is a vital tool for evaluating the workability of fresh concrete, particularly for mixes with high workability or self-compacting properties. Its ability to measure the spread of concrete after jolting provides valuable insights into the mix’s consistency and cohesiveness. This ensures that the concrete will perform well during placement and compaction, reducing the risk of defects and enhancing structural integrity. By integrating the flow table test into routine quality control, engineers and builders can achieve better consistency, durability, and performance in concrete structures, ultimately contributing to safer and longer-lasting construction projects.

4 thoughts on “Flow Table Test for Concrete: Ensuring Concrete Workability”

Comments are closed.