The soundness of the cement is the ability to resist volume changes after hardening. The soundness test on cement is significant because,using unsound cement leads to cracks and hamper the structural quality. A sound cement is one of the key materials used in construction. Therefore it is essential to determine its quality before using it in construction.

Ensuring the quality of cement is essential for the strength and durability of construction projects. The soundness test of cement checks if the cement will maintain its volume after setting, preventing it from expanding and cracking. This test finds any excess lime or magnesia that could cause issues.

In this blog, we will dive deep into the soundness test of cement, covering its procedure, calculation, and importance in making sure construction materials are reliable. You will learn all about the Soundness Test for Cement and why it’s essential for ensuring cement quality. We’ll cover the cement soundness test ways, the step-by-step procedure, and how to interpret the results. By understanding the soundness of cement test, you’ll gain insights into how it impacts construction durability. Whether you’re a professional or a learner, this guide will simplify the soundness test of cement for you.

Table of contents

Types of Tests on Cement

Cement is one of the oldest and most used binding materials and an integral ingredient used in the construction sector. The quality, serviceability, and stability of a structure are directly related to the quality of cement used in it. Hence it is necessary to analyse the quality of cement before using it for works. The tests for determining cement quality are split into two major categories.

- Laboratory test

- Field tests for cement

Field tests on Cement

The quality of cement is determined using some simple field tests. These tests do not require any sophisticated types of equipment and professional skills and get the results very quickly. By conducting these simple tests and analyzing the results we will get an idea about the cement quality and can at once decide on accepting or rejecting it.

Following are the common field tests conducted to ensure the quality of cement

These are first look tests and the quality of cement is ensured by its smoothness to touch, the colour of cement, etc.

- Checking manufacturing date

- Visual checking of lumps

- Feel test

- Heat of cement

- colour

- Water float test

- Setting test

These basic tests give an approximate characteristic of cement. These are easy and quick but not accurate, however help in concluding the acceptance of cement for works.

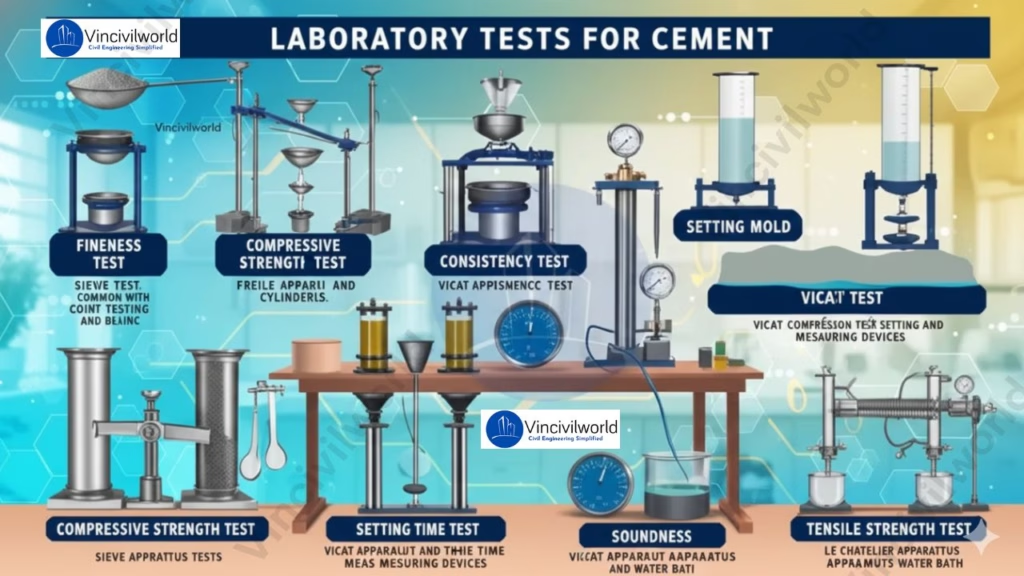

Laboratory tests for Cement

The laboratory tests defines the physical and chemical properties of cement. It is not possible to check all the cement properties at the site. The main laboratory tests conducted on cement is as follows.

- Fineness Test

- Compressive Strength Test

- Consistency Test on cement

- Setting time

- Soundness Test

- Tensile strength Test

- Heat of hydration

Lab tests require time. But it provides accurate results. In this article, we are going to describe the Soundness test on cement.

What is Soundness test of cement ?

The soundness of the cement is the ability to resist volume changes after hardening. The Soundness Test for Cement evaluates how well cement maintains its volume over time, ensuring it does not expand or shrink excessively after setting. The cement soundness test is significant because usage of unsound cement leads to cracks and hamper the structural quality.

The chemical composition of cement consists of lime. About 60 to 70% of cement is lime. The main function of lime is to help cement in the setting process. A good quality cement do not change its volume after hardening.

Following are the reasons for the unsoundness of cement.

- If the cement has an excess amount of lime, expansion or contraction in volume occurs after setting.

- Another reason for unsoundness is the inadequate burning of cement. This leads to cracks, disintegration and a decrease in durability.

- Improper grinding and mixing of raw materials during the manufacturing process of cement.

- Due to the high proportion of magnesium content or sulphate content.

Therefore Soundness test is performed to determine whether the cement shows volume changes or not.

Significance of Soundness test on cement

The Soundness Test for Cement evaluates how well cement maintains its volume over time, ensuring it does not expand or shrink excessively after setting. By performing the soundness of cement test, we can identify any potential issues that might lead to deformation or cracking. The soundness test of cement helps prevent problems in the final structure, ensuring long-term quality and performance. Conducting this test allows engineers to ensure that the cement used meets the necessary standards and maintains its integrity throughout its service life, contributing to overall construction reliability.

Relevant IS code

- IS 4031 (Part 3)-1988

- ASTM C 151-09

- BS EN 196-3: 2005

Standard Methods

Standard methods for the Soundness Test for Cement include the Le Chatelier Method and the Autoclave Test. The Le Chatelier Method measures expansion using a special apparatus with a cement sample and a reference gauge. The Autoclave Test involves curing the cement in a high-pressure steam environment to evaluate its expansion. Both methods help determine if the cement meets required standards for stability and durability. In this article we will emphasis on Le Chatelier Method for Soundness test for cement

Procedure for Soundness Test of Cement

To perform the Soundness Test of Cement, mix cement with water to create a paste and mold it into a specific shape. Using the Le Chatelier Method, measure the expansion of the molded sample with the Le Chatelier apparatus. This method evaluates the cement’s stability by checking for excessive expansion. Accurate measurement ensures that the cement maintains its integrity and does not cause structural issues.

Apparatus required for Le chatelier’s Method

Soundness of cement is calculated by using Le-chatelier’s apparatus.

- Le-Chatelier mould

- Balance

- Water bath

- Vernier Calliper

- Pan and trowel

Le-chatelier mould is made using brass. It consists of a spring-tensioned split cylinder and an indicating long arm in its either side. The internal diameter and height of the cylinder are 30mm and 30mm. The size of glass plates is 50mm x 50 mm. For each test, we need three such moulds. The test should be performed at a temperature of 27 ± 2°C and relative humidity of 50 to 80 per cent as per IS code.

Procedure for soundness test on Cement

Before Performing the test, calculate the standard consistency of cement to find out the water required to obtain the normal consistency(P).

- Take about 100 gm of cement and add 0.78-times the water needed to make cement paste with normal consistency.

- Then grease the glass plate and the Le-chatelier mould to avoid the sticking of cement on its surface.

- Fill the cement paste and strike out the excess cement using a trowel.

- Cover the mould with another glass plate and place a weight above the glass plate.

- Then immerse the whole assembly inside the water bath for 24 hours.

- After 24 hours, take out the mould from water and measure the distance between the indicators.

- Note this measurement as L1. After that place, the assembly in the water bath

- Boil the water for 25 to 30 minutes and leave them for 3 hours.

- After that, allow them to cool till it reaches the room temperature.

- Now take out the assembly and measure the distance between the indicators and mark them as L2.

Calculation

Volume expansion of cement = L1 – L2

L1 is the distance between the indicators after immersing in water for 24 hours

L2 is the distance between the indicators after immersing in water at boiling temperature for 3 hours

This value differs for different types of cement. The expansion of volume for Ordinary portland cement, portland pozzolanic cement, low heat cement and rapid hardening cement should not exceed 10mm. For high alumina cement, super sulphate cement, the volume expansion should not exceed 5mm. Because it contains excess lime or magnesium which is not suitable for construction.

Interpreting the Results

Interpreting results from the Soundness Test for Cement involves assessing whether the cement maintains its volume. The test results indicate if the cement will remain stable and avoid excessive expansion.

What Do the Results Indicate ?

The results of the soundness of cement test show whether the cement expands or contracts after setting. If expansion is within acceptable limits, the cement will remain stable and prevent structural issues.

Acceptable Limits and Standards

Cement soundness test results must meet specific standards, such as those outlined in ASTM C150. Typically, acceptable limits are defined to ensure that expansion remains minimal, ensuring cement’s long-term stability and performance.

Importance Quality Control

The Soundness Test for Cement is crucial in the cement industry for maintaining quality control. It ensures that cement will not expand excessively after setting, preventing structural issues such as cracks. By assessing the soundness of cement, manufacturers can guarantee that their products meet industry standards and provide long-lasting stability. This test directly affects construction quality, as stable cement ensures reliable and durable structures.

Key Takeaways

- The soundness test on Cement assesses its ability to maintain volume after hardening, preventing cracks in structures.

- This test detects excess lime or magnesia in cement that could lead to unsoundness.

- The Le Chatelier Method and Autoclave Test are standard methods for conducting the soundness test on Cement.

- Conducting the soundness test on Cement is crucial for quality control in the construction industry.

- Understanding the results of the soundness test on Cement helps ensure long-term durability and reliability of construction materials.

Conclusion

The Soundness Test for Cement is vital for ensuring the quality and reliability of cement used in construction. By measuring the cement’s ability to resist volume changes, this test helps prevent potential issues like cracks and structural failure. The Le Chatelier Method provides a reliable way to evaluate cement stability, ensuring that it meets industry standards. Conducting this test is essential for achieving durable and high-quality construction, making it a key part of quality control in the cement industry.

One thought on “Soundness Test on Cement: Procedure and Significance”

Comments are closed.